ข้อควรพิจารณาหลักในการเลือกเครื่องพิมพ์แบนเนอร์

ความกว้างและขนาดการพิมพ์

เมื่อเลือกเครื่องพิมพ์แบนเนอร์ ความกว้างและขนาดการพิมพ์ที่เครื่องสามารถทำได้มีความสำคัญมาก โดยเฉพาะอย่างยิ่งเมื่อเกี่ยวข้องกับความต้องการเฉพาะของโครงการต่าง ๆ การพิมพ์ในรูปแบบขนาดใหญ่มีความสำคัญอย่างมากสำหรับผู้ที่ทำงานด้านการโฆษณา หรือการวางแผนจัดกิจกรรม ซึ่งต้องการภาพแสดงผลขนาดใหญ่ที่สะดุดตา ธุรกิจได้รับประโยชน์อย่างมากจากเครื่องพิมพ์ที่รองรับงานพิมพ์หลายขนาด ตั้งแต่ป้ายขนาดเล็กสำหรับร้านค้าไปจนถึงแบนเนอร์ขนาดใหญ่สำหรับนิทรรศการ มาตรฐานของอุตสาหกรรมนั้นมีความแตกต่างกันค่อนข้างมาก ซึ่งส่งผลต่อรูปลักษณ์ของแบบที่พิมพ์ออกมา ตัวอย่างเช่น แบนเนอร์สำหรับงานแสดงสินค้าโดยทั่วไปมักมีความกว้างประมาณ 48 นิ้ว เพราะขนาดนี้เหมาะสำหรับการแสดงภาพที่มีรายละเอียดครบถ้วน ดึงดูดความสนใจได้ดี โดยไม่รู้สึกอึดอัด บริษัทส่วนใหญ่พบว่าความหลากหลายนี้มีความจำเป็นอยู่แล้ว จากการสำรวจความคิดเห็นของลูกค้าและข้อมูลการขายที่ผ่านมา เราได้เห็นอยู่บ่อยครั้งว่าการมีตัวเลือกหลายขนาดช่วยเพิ่มความพึงพอใจให้กับลูกค้าหลังการซื้อโดยรวม

ความเข้ากันได้กับวัสดุ (รวมถึงการพิมพ์ผ้าตามแบบเฉพาะ)

เครื่องพิมพ์แบนเนอร์ที่ดีจำเป็นต้องทำงานได้ดีกับวัสดุหลากหลายประเภท เช่น ไวนิล ผ้า และกระดาษธรรมดา เพราะลูกค้าในปัจจุบันต้องการให้สิ่งต่าง ๆ พิมพ์ลงบนวัสดุทุกประเภทที่มีอยู่ งานพิมพ์บนผ้าได้รับความนิยมเพิ่มขึ้นมากในช่วงงานแสดงสินค้าที่ผ่านมา เนื่องจากบริษัทต่าง ๆ ชอบที่จะสามารถติดตั้งการแสดงผลที่สะดุดตาและโดดเด่นกว่าคู่แข่งขัน ก่อนที่จะเริ่มดำเนินการพิมพ์จริง ร้านค้าส่วนใหญ่จะทดสอบตัวอย่างบนพื้นผิวที่แตกต่างกัน เพื่อดูว่าหมึกยึดติดได้ดีเพียงใด และผลงานที่ได้มีลักษณะเป็นอย่างไรเมื่อเสร็จสมบูรณ์ ตัวเลขก็สนับสนุนเรื่องนี้เช่นกัน โดยร้านพิมพ์หลายแห่งรายงานว่ากำไรเพิ่มขึ้นเมื่อพวกเขามีวัสดุหลายประเภทให้เลือก ลูกค้ามักจะถูกใจธุรกิจที่สามารถรับมือกับโครงการที่แปลกประหลาดที่สุดที่อาจเกิดขึ้นต่อไป ซึ่งเป็นเรื่องที่เข้าใจได้เมื่อพยายามขยายฐานลูกค้าในอุตสาหกรรมที่หลากหลายที่ต้องการโซลูชันป้ายแบบกำหนดเอง

ความต้องการใช้งานภายในอาคารและภายนอกอาคาร

การรู้ว่าเมื่อใดควรใช้เครื่องพิมพ์ที่ออกแบบมาสำหรับงานภายในอาคาร เทียบกับเครื่องพิมพ์ที่สร้างมาเพื่อใช้ภายนอกอาคารนั้นมีความสำคัญอย่างมากในธุรกิจการพิมพ์ เมื่อพูดถึงป้ายโฆษณาที่ใช้ภายนอกอาคาร ป้ายเหล่านี้ต้องสามารถทนต่อความเสียหายจากแสงแดด ฝน หิมะ และการเปลี่ยนแปลงของอุณหภูมิหลากหลายรูปแบบ ซึ่งส่งผลต่อประเภทวัสดุที่เลือกใช้รวมถึงหมึกพิมพ์ที่นำมาใช้ในกระบวนการ สำหรับป้ายโฆษณาภายในอาคารนั้นเรื่องราวจะต่างออกไปโดยสิ้นเชิง โดยทั่วไปผู้คนมักกังวลเกี่ยวกับความสวยงามและรายละเอียด เช่น ความชัดเจนของตัวหนังสือ เนื่องจากไม่มีใครคาดหวังว่าป้ายเหล่านี้จะต้องทนต่อสภาพอากาศเลวร้าย ป้ายที่ใช้ภายนอกอาคารสามารถพบเห็นได้ทั่วไปตามหัวมุมถนนหรือลานจอดรถในช่วงเทศกาลต่างๆ ในขณะที่ป้ายภายในอาคารมักพบเห็นได้ตามร้านค้าหรืองานประชุมสัมมนา ซึ่งสภาพอากาศถูกควบคุมให้คงที่ตลอดเวลา ความแตกต่างนี้ยังแสดงให้เห็นได้อย่างชัดเจนในระยะยาวอีกด้วย วัสดุที่พิมพ์สำหรับใช้ภายนอกอาคารจะไม่สามารถคงทนได้นาน หากไม่ได้ผลิตจากวัสดุที่มีความทนทานเป็นพิเศษซึ่งสามารถต้านทานการซีดจางหลังจากถูกแสงแดดจัดเป็นเวลานานหลายเดือน

การประเมินเทคโนโลยีการพิมพ์สำหรับแบนเนอร์

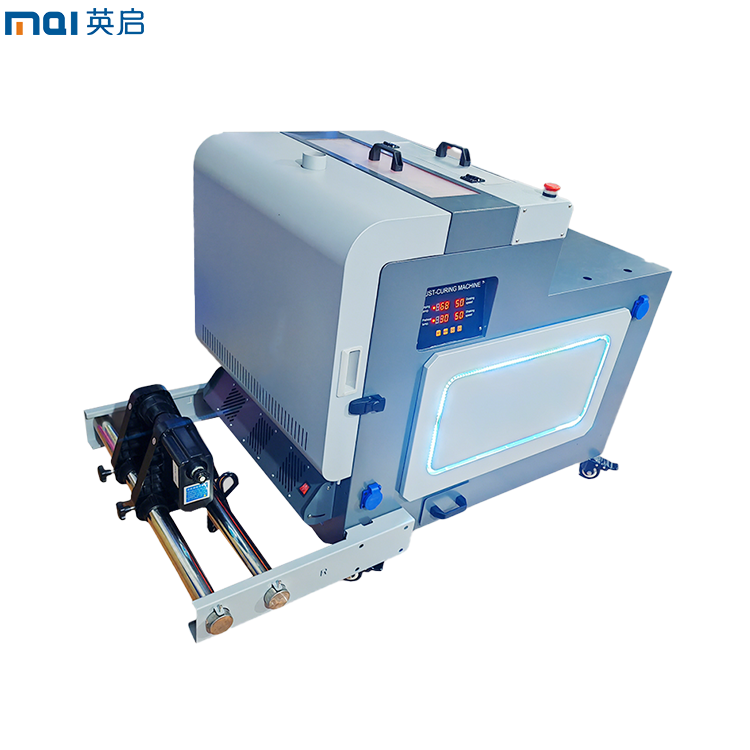

เครื่องพิมพ์ UV เพื่อสีสันที่สดใสและทนทาน

การพิมพ์แบบ UV ถือเป็นก้าวสำคัญในการทำให้ภาพพิมพ์มีความสดใสและคงทนยาวนานมากยิ่งขึ้น สิ่งที่ทำให้เทคโนโลยีนี้โดดเด่นคือการใช้แสงอัลตราไวโอเลตในการทำให้หมึกแห้งทันทีหลังพิมพ์เสร็จ ซึ่งช่วยให้ได้รายละเอียดคมชัดและสีสันสดใสสะดุดตาที่ทุกคนชื่นชอบ ข้อได้เปรียบหลักของหมึก UV คือการแห้งเร็วมาก และทนทานต่อสภาพอากาศภายนอกได้ดีแม้จะเจอสภาพอากาศเปลี่ยนแปลง เช่น ฝนตกหรือแดดจัด ตัวอย่างเช่น งานแสดงสินค้า แบนเนอร์ที่พิมพ์ด้วยเทคโนโลยี UV จะยังคงสภาพสดใหม่แม้ต้องเจอกับฝนหรือแดดแผดเผา รายงานจากอุตสาหกรรมมักจะชี้ให้เห็นว่า การพิมพ์แบบ UV ให้ผลลัพธ์เหนือกว่าวิธีการพิมพ์แบบดั้งเดิม โดยเฉพาะเรื่องสีสันที่ไม่จางหายไปอย่างรวดเร็วเมื่อถูกแสงแดดหรือความชื้น นั่นจึงเป็นเหตุผลว่าทำไมบริษัทจำนวนมากจึงหันมาใช้เครื่องพิมพ์ UV สำหรับงานต่างๆ เช่น ป้ายแสดงในบูธงานสัมมนา หรือแคมเปญโฆษณาภายนอกอาคาร ที่ซึ่งการมองเห็นได้ชัดเจนในระยะยาวมีความสำคัญมาก

Solvent vs. Eco-Solvent Inks สำหรับการใช้งานภายนอกอาคาร

สำหรับผู้ที่กำลังพิจารณาเรื่องหมึกพิมพ์สำหรับการพิมพ์แบนเนอร์ภายนอกอาคาร การรู้ความแตกต่างระหว่างหมึกโซเวนต์ธรรมดาและหมึกอีโคโซเวนต์นั้นมีความสำคัญอย่างมาก หมึกโซเวนต์ยึดติดกับพื้นผิวได้ดีและทนทานต่อฝนแดดและลม ซึ่งเป็นเหตุผลที่หมึกชนิดนี้มักถูกเลือกใช้สำหรับป้ายที่ต้องอยู่ภายนอกได้นานหลายเดือน แต่ก็มีข้อเสียที่ควรกล่าวถึง คือ หมึกเหล่านี้มีสารเคมีที่อาจส่งผลกระทบต่อสิ่งแวดล้อม จึงมีทางเลือกอื่นที่เรียกว่าหมึกอีโคโซเวนต์ แม้จะยังคงความทนทานเพียงพอสำหรับงานภายนอกอาคารส่วนใหญ่ แต่หมึกใหม่ชนิดนี้ปล่อย VOCs (สารประกอบอินทรีย์ระเหยได้) ที่เป็นอันตรายต่อสิ่งแวดล้อมน้อยกว่ามาก ซึ่งในช่วงหลังนี้หน่วยงานกำกับดูแลให้ความสนใจมากขึ้น อุตสาหกรรมนี้ได้เห็นการเปลี่ยนแปลงที่ชัดเจนไปสู่การใช้หมึกอีโคโซเวนต์ในช่วงไม่กี่ปีที่ผ่านมา โดยหลักแล้วเป็นเพราะธุรกิจต้องการทางเลือกที่เป็นมิตรกับสิ่งแวดล้อมมากขึ้นโดยไม่เพิ่มต้นทุนมากเกินไป ร้านทำปัจจุบันสต็อกทั้งสองประเภทไว้ เพื่อให้ลูกค้าสามารถเลือกได้ตามงบประมาณและความต้องการว่าป้ายจะต้องคงอยู่นานแค่ไหน ส่วนป้ายบิลบอร์ดหรือการตกแต่งหน้าร้านที่ต้องเผชิญกับสภาพอากาศที่ยากลำบาก หมึกอีโคโซเวนต์ยังถือเป็นทางเลือกที่ดีแม้ว่าจะยังมีการถกเถียงกันอยู่ว่าหมึกอีโคโซเวนต์สามารถแทนที่โซเวนต์แบบดั้งเดิมได้สมบูรณ์หรือไม่

เครื่องพิมพ์แลเท็กซ์: ตัวเลือกที่เป็นมิตรกับสิ่งแวดล้อมและใช้งานหลากหลาย

ในปัจจุบัน บริษัทต่างๆ หันมาใช้การพิมพ์ด้วยแลตเท็กซ์กันมากขึ้น เนื่องจากเป็นมิตรกับสิ่งแวดล้อมและสามารถใช้งานได้เกือบทุกที่ การเปลี่ยนแปลงที่สำคัญที่สุดเมื่อเทียบกับการพิมพ์แบบดั้งเดิมที่ใช้สารเคมีแก้ปัญหา (Solvent-based printing) คือ การใช้หมึกที่ละลายน้ำได้แทนสารเคมีที่เป็นอันตราย ซึ่งช่วยให้อากาศภายในร้านพิมพ์สะอาดขึ้น และสภาพการทำงานปลอดภัยมากขึ้นสำหรับพนักงาน นอกจากนี้ หมึกแลตเท็กซ์ยังได้รับความนิยมเนื่องจากสีไม่ซีดจางง่าย และทนต่อรอยขีดข่วน ทำให้วัสดุที่พิมพ์ออกมาใช้งานได้นาน ไม่ว่าจะนำไปติดตั้งบนผนังหรือวางไว้ภายนอกอาคาร อะไรที่ทำให้เครื่องพิมพ์แลตเท็กซ์ได้รับความนิยม? พวกเขารับมือกับงานหลากหลายประเภท เช่น โปสเตอร์ในร้านค้าปลีก โฆษณาขนาดใหญ่บนตึก หรือแม้แต่วัสดุประชาสัมพันธ์ตามงานแสดงสินค้า ตามรายงานตลาดล่าสุด ยอดขายเพิ่มขึ้นอย่างมาก เนื่องจากธุรกิจต่างๆ กำลังมองหาทางเลือกที่เป็นมิตรกับสิ่งแวดล้อม จุดเด่นอีกประการหนึ่งคือ คุณภาพของการพิมพ์ที่สม่ำเสมอไม่ว่าจะพิมพ์บนวัสดุประเภทใด ซึ่งมีความสำคัญมากเมื่อสร้างสื่อแสดงผลที่สะดุดตา หรือวัสดุการตลาดที่ดูเป็นมืออาชีพ เมื่ออุตสาหกรรมต่างๆ เริ่มจริงจังกับแนวทางการรักษาสิ่งแวดล้อม งานพิมพ์แบบแลตเท็กซ์จึงกลายเป็นทางเลือกที่โดดเด่น ด้วยการผสมผสานเทคโนโลยีทันสมัยเข้ากับประโยชน์เชิงสิ่งแวดล้อมที่แท้จริง

ข้อมูลจำเพาะที่สำคัญสำหรับผลงานที่มีผลกระทบสูง

ความละเอียดและความแม่นยำของสี

การได้ภาพความละเอียดสูงที่ถูกต้องมีความสำคัญมากเมื่อสร้างแบนเนอร์ที่ดึงดูดสายตา ผู้คนส่วนใหญ่ใช้หน่วย DPI (จุดต่อนิ้ว) ในการวัดความละเอียด โดยทั่วไปตัวเลขที่สูงขึ้นหมายถึงรายละเอียดที่ชัดเจนกว่าในภาพพิมพ์ สิ่งที่สำคัญมากสำหรับงานที่ต้องการความเป็นมืออาชีพ สีสันก็ต้องแม่นยำเช่นกัน เพราะแบรนด์ต่างๆ ต้องการให้โลโก้และข้อความของตนมีลักษณะสม่ำเสมอในทุกวัสดุที่ใช้ งานวิจัยแสดงให้เห็นว่าผู้คนมักจะชอบการพิมพ์ที่สีสันสดใสและคมชัดมากกว่าแบบจืดชืด ดังนั้นการลงทุนในเทคโนโลยีการพิมพ์ที่มีคุณภาพจึงเป็นเรื่องที่สมเหตุสมผลสำหรับธุรกิจที่ต้องการให้ลูกค้าสังเกตเห็นพวกเขา การปรับเทียบให้ถูกต้องร่วมกับเครื่องมือจัดการสีที่ดีสามารถสร้างความแตกต่างที่สำคัญในการผลิตสีสันให้ตรงตามต้นฉบับ ทำให้แต่ละแบนเนอร์มีลักษณะเหมือนกับที่ถูกออกแบบมาตั้งแต่แรกจนจบ

ความเร็วในการพิมพ์และอัตราการผลิต

การมีความเร็วในการพิมพ์ที่ดีและอัตราการผลิตที่เหมาะสมมีความสำคัญอย่างมากต่อการรักษากระบวนการทำงานให้ราบรื่น โดยเฉพาะในสถานที่ที่ต้องผลิตเอกสารหลายพันหน้าต่อวัน เช่น บริษัทโฆษณา หรือสำนักพิมพ์ เมื่อบริษัทสามารถหาจุดลงตัวระหว่างความเร็วในการพิมพ์และความละเอียดของงานที่ลูกค้ายอมรับได้ ทุกฝ่ายต่างได้รับประโยชน์ ตลาดปัจจุบันเต็มไปด้วยเครื่องพิมพ์ที่เคลมว่ามีตัวเลขประสิทธิภาพน่าประทับใจ ดังนั้นการดูผลทดสอบจริงจากเว็บไซต์รีวิวน่าเชื่อถือ จะช่วยให้เลือกได้ว่าเครื่องไหนเหมาะกับงานประเภทใดมากที่สุด การพิมพ์ที่รวดเร็วขึ้นหมายถึงเวลาที่ลูกค้าต้องรอจะลดลง และจำนวนงานที่ส่งช้าในฝั่งการผลิตก็จะลดตามไปด้วย สำหรับธุรกิจที่ความรวดเร็วในการดำเนินงานเป็นหัวใจสำคัญ การเลือกเครื่องจักรที่ผสมผสานความเร็วเข้ากับคุณภาพที่ยอมรับได้ จึงเป็นสิ่งจำเป็นอย่างยิ่งเพื่อรักษาความสามารถในการแข่งขันในตลาดเฉพาะของตนเอง

คุณสมบัติการเชื่อมต่อ (การผนวกรวมเครือข่าย)

เครื่องพิมพ์แบนเนอร์ในปัจจุบันมักมาพร้อมกับคุณสมบัติการเชื่อมต่อที่ช่วยเพิ่มประสิทธิภาพในการผสานรวมเข้ากับกระบวนการทำงานขององค์กรอย่างมาก โดยส่วนใหญ่แล้วโมเดลต่าง ๆ จะมี Bluetooth, พอร์ต USB และการเชื่อมต่อแบบไร้สาย ซึ่งช่วยให้ผู้ใช้งานสามารถจัดการงานพิมพ์จากทุกที่ภายในพื้นที่สำนักงานได้ ตัวอย่างเช่น ทีมการตลาดที่กำลังทำงานเกี่ยวกับสื่อประชาสัมพันธ์สำหรับกิจกรรมหนึ่ง สามารถส่งไฟล์ไปยังเครื่องพิมพ์ได้โดยตรงจากแล็ปท็อปของตน โดยไม่ต้องเชื่อมต่อสายใด ๆ เลย เมื่อองค์กรมีการพึ่งพาเทคโนโลยีที่เชื่อมต่อได้ระหว่างแผนกต่าง ๆ เพิ่มมากขึ้น การเชื่อมโยงระบบการพิมพ์เข้ากับซอฟต์แวร์ออกแบบดิจิทัลจึงกลายเป็นมาตรฐานปฏิบัติที่เกือบจะจำเป็น โครงสร้างแบบเชื่อมโยงเครือข่ายนี้ช่วยลดเวลาที่เสียไปและข้อผิดพลาดต่าง ๆ ระหว่างการผลิต ในอนาคตข้างหน้า ผู้ผลิตต่างมุ่งเน้นการปรับปรุงการเชื่อมต่อเหล่านี้ให้ดียิ่งขึ้น เพื่อให้บริษัทต่าง ๆ สามารถดำเนินการให้ได้ผลลัพธ์รวดเร็วขึ้น พร้อมทั้งรักษามาตรฐานคุณภาพตลอดกระบวนการพิมพ์ไว้ได้

การจัดงบประมาณสำหรับการลงทุนในเครื่องพิมพ์แบนเนอร์

ค่าใช้จ่ายในการซื้อครั้งแรก เทียบกับค่าใช้จ่ายระยะยาว

การลงทุนในเครื่องพิมพ์แบนเนอร์ หมายถึงการพิจารณาทั้งราคาในตอนนี้ และค่าใช้จ่ายที่อาจเกิดขึ้นในระยะยาว ค่าใช้จ่ายเบื้องต้นนั้นเข้าใจได้ง่ายพอสมควร นั่นคือราคาของเครื่องพิมพ์เอง รวมถึงค่าติดตั้งและค่าใช้จ่ายในการตั้งค่าต่าง ๆ แต่ยังมีค่าใช้จ่ายอื่น ๆ ที่เกิดขึ้นต่อเนื่อง ซึ่งหลายคนมักไม่ได้พูดถึงในตอนแรก เช่น การบำรุงรักษาเป็นประจำ การซื้อหมึกพิมพ์และวัสดุสิ้นเปลืองอย่างต่อเนื่อง ไม่ต้องพูดถึงค่าซ่อมแซมที่ไม่คาดคิดเมื่อเครื่องเกิดปัญหาเสียหาย หลายคนมักหลงใหลในโมเดลราคาถูก เพราะดูดีในระยะสั้นตอนแรกเห็น แต่เครื่องพิมพ์เหล่านี้กลับกินเงินไปอย่างรวดเร็ว เนื่องจากปัญหาความไม่มีประสิทธิภาพ หรือประสิทธิภาพโดยรวมที่แย่ ซึ่งส่งผลให้ประสิทธิภาพการผลิตลดลง ผู้เชี่ยวชาญในอุตสาหกรรมหลายคนแนะนำให้ทำการวิเคราะห์ค่าใช้จ่ายทั้งหมดอย่างละเอียดก่อนตัดสินใจเกี่ยวกับผลตอบแทนจากการลงทุน (ROI) การมองภาพรวมในลักษณะนี้จะช่วยให้ธุรกิจสามารถเลือกเครื่องพิมพ์ที่ใช้งานได้ดีในระยะยาว แทนที่จะต้องเปลี่ยนชิ้นส่วนอยู่ตลอดเวลา หรือแก้ไขปัญหาซ้ำ ๆ ซึ่งจะเพิ่มค่าใช้จ่ายขึ้นอย่างรวดเร็ว

ประสิทธิภาพของหมึกพิมพ์และการวิเคราะห์ต้นทุนต่อการพิมพ์

เมื่อพูดถึงการพิมพ์แบนเนอร์ ไม่มีใครใส่ใจเรื่องประสิทธิภาพของหมึกพิมพ์มากไปกว่าเจ้าของธุรกิจที่ต้องคอยจับตาดูงบประมาณของตนเอง ท้ายที่สุดแล้ว ทุกหยดที่สูญเปล่า หมายถึงต้นทุนการดำเนินงานที่เพิ่มขึ้น เครื่องพิมพ์ที่ดีที่สุดในท้องตลาดในปัจจุบันมีเทคโนโลยีอัจฉริยะที่ช่วยให้ใช้หมึกจากแต่ละตลับได้คุ้มค่าที่สุด พร้อมทั้งลดจุดที่หมึกเสียเปล่าที่เราทุกคนต่างเคยประสบพบเจอ ต้องการทราบว่าสิ่งใดสิ่งหนึ่งนั้นมีราคาเท่าไรจริงๆ ให้เริ่มจากการคำนวณต้นทุนต่อการพิมพ์แต่ละหน้าก่อนเป็นอันดับแรก อย่าลืมคำนึงถึงไม่เพียงแค่ปริมาณหมึกที่ใช้ไป แต่รวมถึงประเภทของวัสดุที่นำมาใช้ในการพิมพ์ด้วย การเปลี่ยนมาใช้ตลับหมึกที่มีความจุขนาดใหญ่สามารถสร้างความแตกต่างได้อย่างมหาศาลในระยะยาว มีร้านค้าหลายแห่งรายงานว่าประหยัดเงินได้หลายพันบาทหลังจากอัปเกรดเป็นระบบและหมึกพิมพ์ที่มีประสิทธิภาพ ซึ่งตัวเลขเหล่านี้ไม่ได้เป็นเพียงแค่ตัวเลขบนกระดาษเท่านั้น แต่สามารถแปลงเป็นเงินที่ประหยัดได้จริงทุกเดือน สำหรับทุกๆ องค์กรที่จริงจังกับการควบคุมงบประมาณการพิมพ์ การใช้หมึกพิมพ์อย่างชาญฉลาดไม่ใช่ทางเลือกอีกต่อไป หากต้องการรักษาความสามารถในการแข่งขันและเป็นมิตรกับสิ่งแวดล้อมไปพร้อมกัน

ปัจจัยพิจารณาเกี่ยวกับ ROI สำหรับแคมเปญโฆษณา

การมีเครื่องพิมพ์แบนเนอร์ที่มีคุณภาพดีนั้นสร้างความแตกต่างอย่างชัดเจนเมื่อพิจารณาถึงผลตอบแทนทางการเงินที่ได้จากการลงทุนด้านการโฆษณา แบนเนอร์ที่สั่งทำพิเศษและมีคุณภาพพอใช้ มักช่วยเพิ่มยอดขายได้ เนื่องจากสามารถแสดงเนื้อหาที่ต้องการโปรโมตอย่างชัดเจน และสามารถดึงดูดความสนใจของผู้คนที่เดินผ่านไปมา ตัวเลขก็ยืนยันเรื่องนี้เช่นกัน - ธุรกิจหลายแห่งพบว่ารายได้เพิ่มมากขึ้นหลังจากติดตั้งแบนเนอร์โปรโมต และยังช่วยประหยัดค่าใช้จ่าย เนื่องจากไม่ต้องจ้างบริษัทภายนอกมาพิมพ์อีกต่อไป ร้านค้าขนาดเล็กจำนวนมากยืนยันว่าผลตอบแทนจากการโฆษณาดีขึ้น เมื่อพวกเขาเริ่มพิมพ์แบนเนอร์เอง ซึ่งทำให้พวกเขามีการควบคุมทั้งหมดในเรื่องรูปลักษณ์และคุณภาพ โดยไม่ต้องเสียค่าธรรมเนียมเพิ่มให้กับคนกลาง รายงานจากอุตสาหกรรมยืนยันอย่างต่อเนื่องว่า แบนเนอร์มีประสิทธิภาพยอดเยี่ยมในการดึงดูดความสนใจ และกระตุ้นให้ผู้คนมีปฏิสัมพันธ์กับแบรนด์ สำหรับผู้ที่กำลังคิดจะซื้อเครื่องพิมพ์แบนเนอร์ การคำนึงถึงปัจจัยทางการเงินทั้งหมดเหล่านี้ จะช่วยให้ตัดสินใจได้ว่าการลงทุนนี้คุ้มค่าหรือไม่ โดยเฉพาะเมื่อพิจารณาถึงการเติบโตในระยะยาวและความสำเร็จของแคมเปญ

การรับประกันความน่าเชื่อถือและการใช้งานง่าย

การรับประกันและตัวเลือกการสนับสนุนทางเทคนิค

การพิจารณารับประกันและบริการสนับสนุนทางเทคนิคถือเป็นเรื่องสำคัญมากเมื่อเลือกซื้อเครื่องพิมพ์แบนเนอร์ หากต้องการอุปกรณ์ที่มีความน่าเชื่อถือ บริษัทส่วนใหญ่มักเสนอการรับประกันมาตรฐานสำหรับชิ้นส่วนที่ชำรุด แต่การเพิ่มการคุ้มครองเพิ่มเติมอาจช่วยลดปัญหาในอนาคตที่อาจเกิดขึ้นได้ บริการสนับสนุนทางเทคนิคก็สำคัญไม่แพ้กัน เมื่อเจ้าหน้าที่เทคนิคตอบกลับอย่างรวดเร็ว จะช่วยให้การทำงานดำเนินไปอย่างต่อเนื่องโดยไม่เกิดความล่าช้า เรื่องนี้มีการยืนยันจากความคิดเห็นของลูกค้าที่ผ่านมา ซึ่งองค์กรต่างๆ รายงานว่าประสบกับประสบการณ์ที่ดีกว่ามากเมื่อปัญหาของพวกเขาได้รับการแก้ไขอย่างรวดเร็วแทนที่จะต้องรอเป็นเวลานาน บริษัทที่มีวิสัยทัศน์กว้างไกลมักคำนึงถึงประเด็นเหล่านี้ตั้งแต่แรกเริ่ม มากกว่าจะรอให้เกิดปัญหาขึ้นเสียก่อน การเตรียมการล่วงหน้าในรายละเอียดเหล่านี้จะช่วยป้องกันการหยุดชะงักที่สร้างความหงุดหงิด และทำให้ระบบทำงานได้อย่างราบรื่นในระยะยาว

การใช้งานที่เป็นมิตรสำหรับผู้เริ่มต้น

เมื่อพูดถึงธุรกิจที่มีพนักงานใหม่จำนวนมาก ความง่ายในการใช้งานถือเป็นสิ่งสำคัญมาก ดีไซน์อินเทอร์เฟซที่ดีจะช่วยเพิ่มประสิทธิภาพและความพึงพอใจของพนักงาน เนื่องจากพวกเขาไม่ต้องเสียเวลามากมายในการทำความเข้าใจระบบ หน้าจอแบบสัมผัส รูปแบบการจัดวางที่เรียบง่าย และส่วนช่วยเหลือที่มีอยู่ในตัว ช่วยให้ผู้เริ่มต้นใช้งานสามารถใช้งานได้ง่าย แท้จริงแล้วอุปกรณ์พิมพ์แบนเนอร์สมัยใหม่ส่วนใหญ่ได้รวมคุณสมบัติลักษณะเช่นนี้เข้าไว้ภายในตั้งแต่แรก เพื่อให้ทุกคนในทีมสามารถเรียนรู้และเริ่มใช้งานได้อย่างรวดเร็ว พนักงานใหม่ที่เริ่มต้นใช้งานเครื่องจักรเหล่านี้มักจะกล่าวถึงความชื่นชมในปุ่มที่ออกแบบชัดเจน พร้อมคำแนะนำแบบเป็นขั้นตอนที่มีให้ บริษัทที่ให้ความสำคัญกับการทำให้อุปกรณ์ใช้งานง่าย มักจะพบว่าการตั้งค่าใช้เวลาน้อยลง และเกิดข้อผิดพลาดน้อยลงระหว่างการผลิต

การบํารุงรักษาประจําการ

การรักษาเครื่องพิมพ์แบนเนอร์ให้ทำงานได้อย่างราบรื่นจำเป็นต้องมีการบำรุงรักษาเป็นประจำ การทำความสะอาดหัวฉีด การตรวจสอบการจัดแนว และการตรวจดูชิ้นส่วนที่สึกหรอ เป็นขั้นตอนมาตรฐานที่ช่วยป้องกันเครื่องเสียหาย และทำให้งานพิมพ์มีความคมชัด ร้านค้าส่วนใหญ่พบว่าการปฏิบัติตามกำหนดการบำรุงรักษาช่วยลดปัญหาที่อาจเกิดขึ้นในระยะยาว ซึ่งจะเห็นได้ชัดเจนหลังจากใช้งานไปได้สักระยะหนึ่ง ผู้ผลิตเครื่องพิมพ์มักจะระบุช่วงเวลาในการให้บริการบำรุงรักษาอย่างละเอียดในคู่มือ แสดงให้เห็นว่าการดูแลรักษาอย่างสม่ำเสมอช่วยยืดอายุการใช้งานของเครื่องได้อย่างไร เมื่อกิจการละเลยการตรวจสอบตามกำหนด บ่อยครั้งที่ต้องเผชิญกับค่าซ่อมแซมที่สูงหรือคุณภาพการพิมพ์ที่ไม่ดีในภายหลัง เวลาที่ลงทุนไปกับการบำรุงรักษาอย่างเหมาะสมโดยทั่วไปแล้วจะแปลงออกมาเป็นมูลค่าที่ดีกว่าตลอดอายุการใช้งานของเครื่องพิมพ์

ข่าวเด่น

ข่าวเด่น