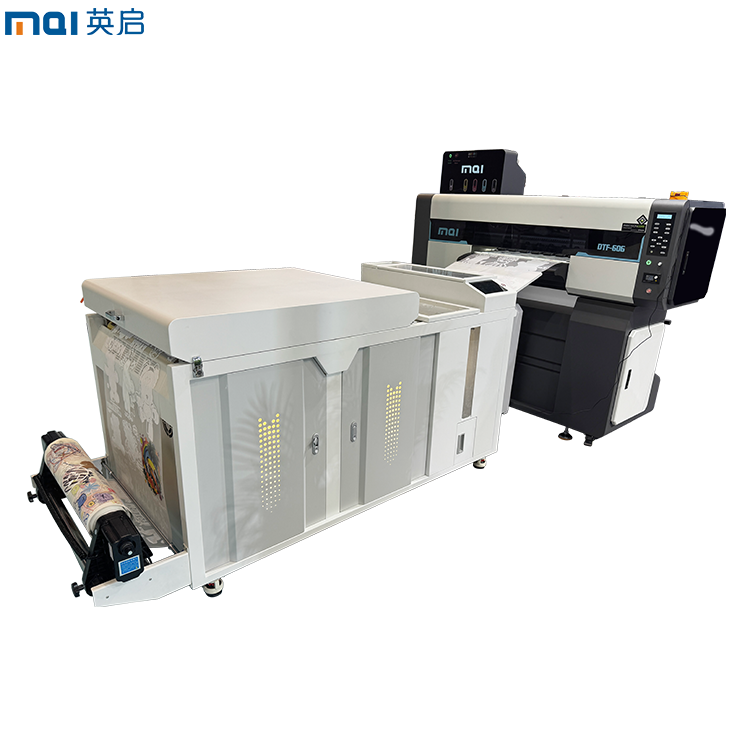

UV flatbed printer

- Model: 6090 3H

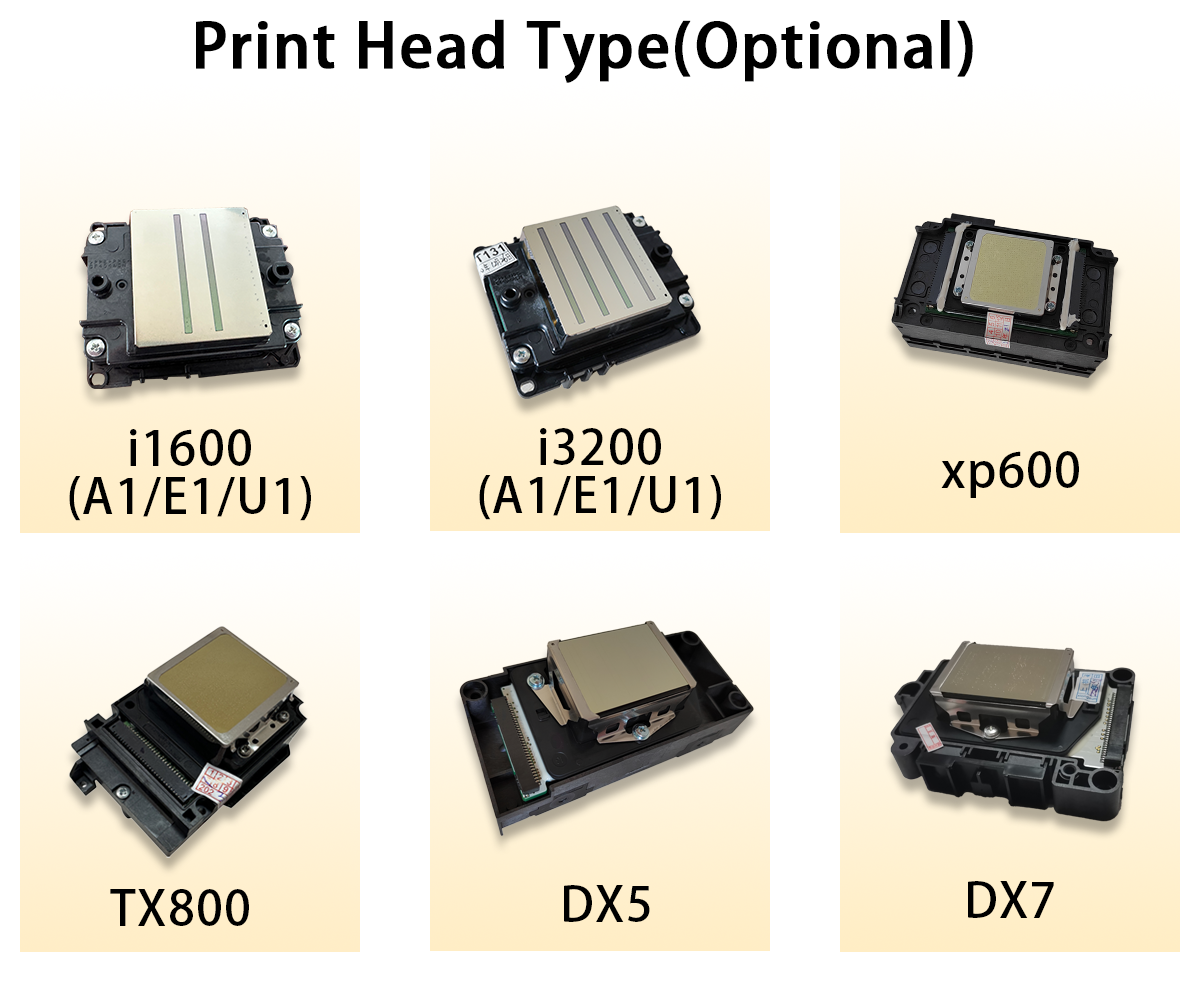

- Printhead: EPSON i3200U1/xp600

- Quantity of printhead: 3pcs

- Printing size: 600*900mm

- RIP software: Maintop

- Ink color: CMYK+W+vanish / CMYK lc lm+W+vanish

- Max resolution: 720x1440DPI

- Printing thickness: 0mm-140mm

- Overview

- Recommended Products

Description

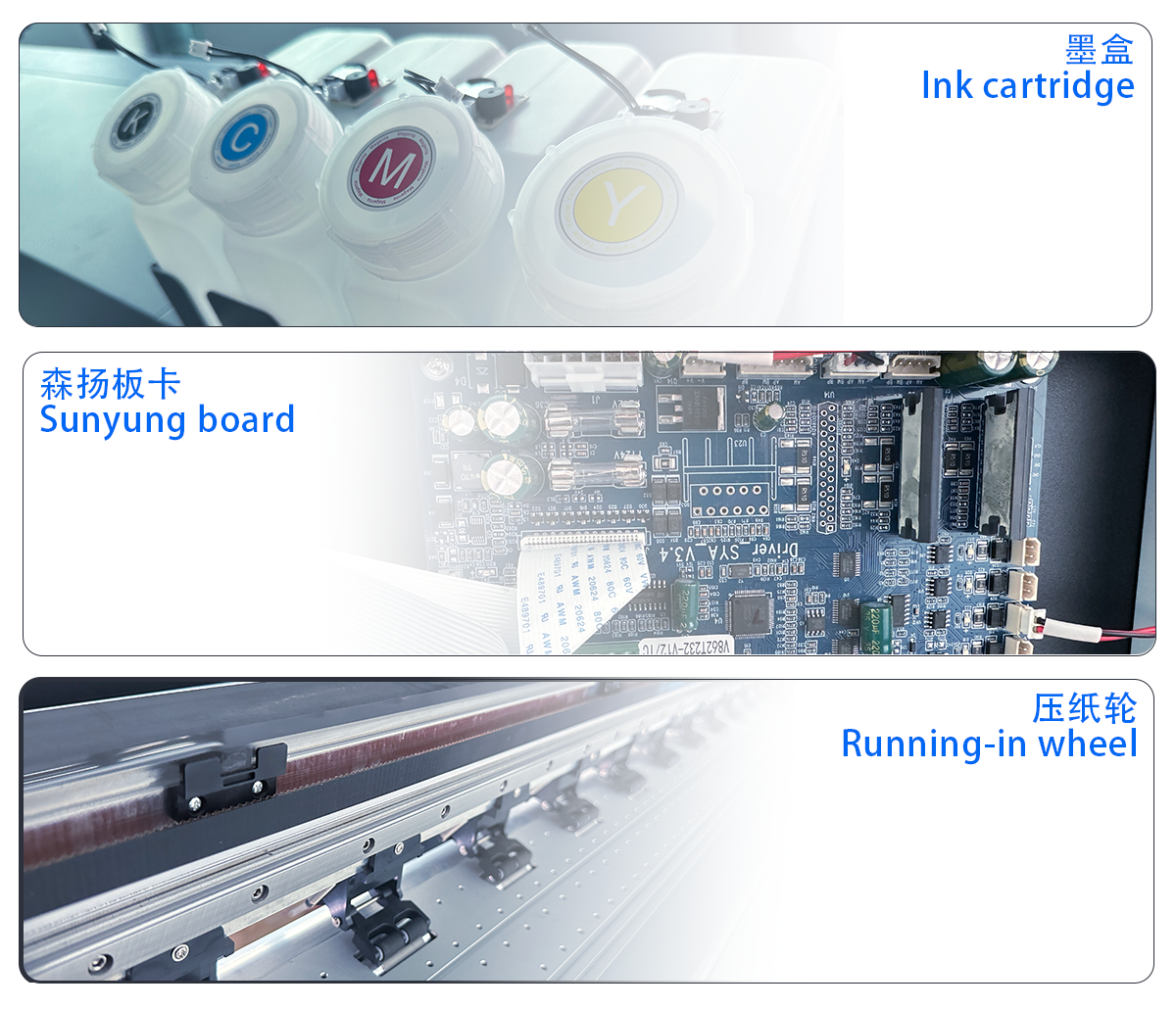

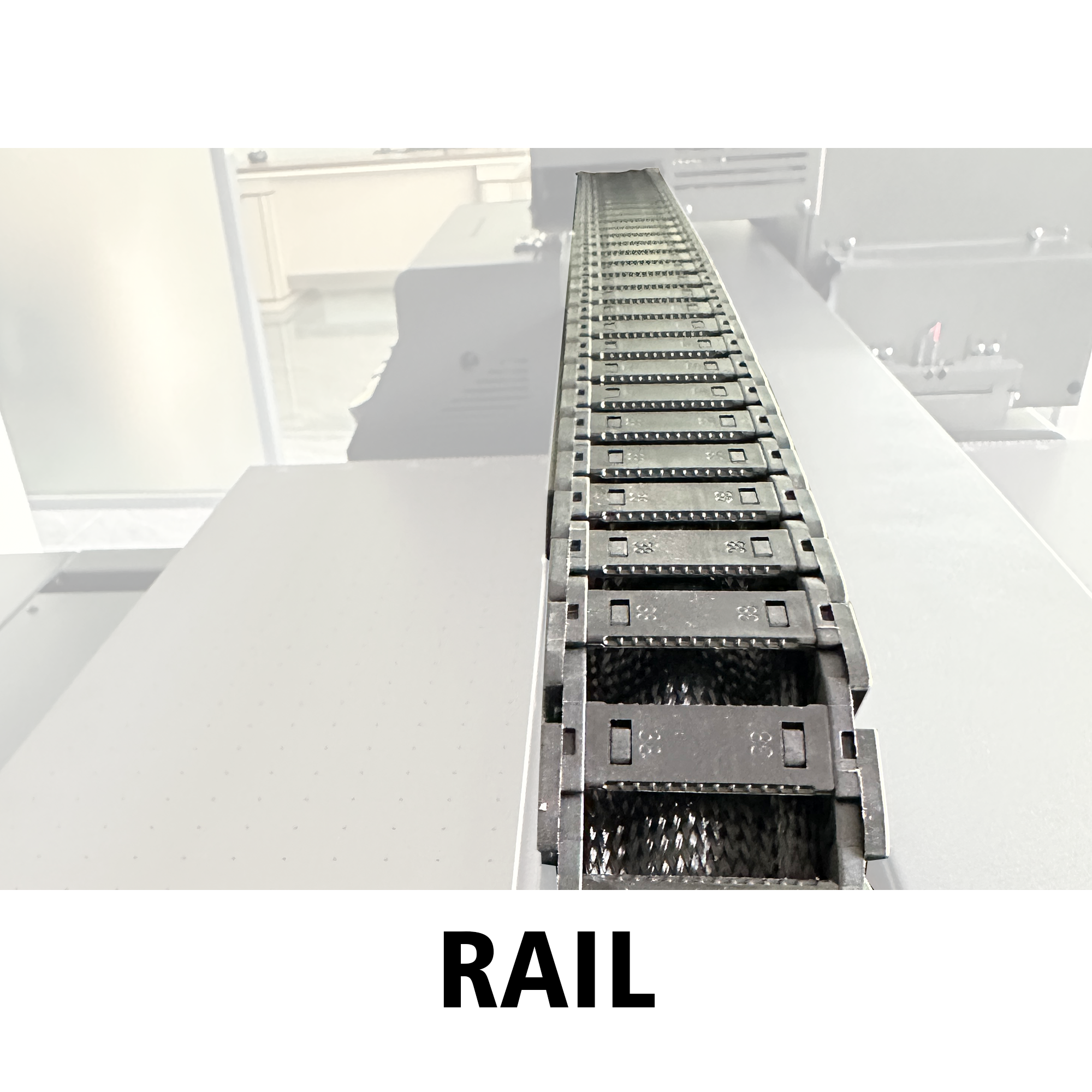

The 6090UV flatbed machine uses advanced UV curing inkjet technology, and the print head accurately sprays UV ink containing photosensitive components. It is quickly cured by UV lamp irradiation, achieving instant printing and drying. It is equipped with a high-performance print head, coupled with a high-precision guide rail, screw and motor transmission system to ensure accurate printing.

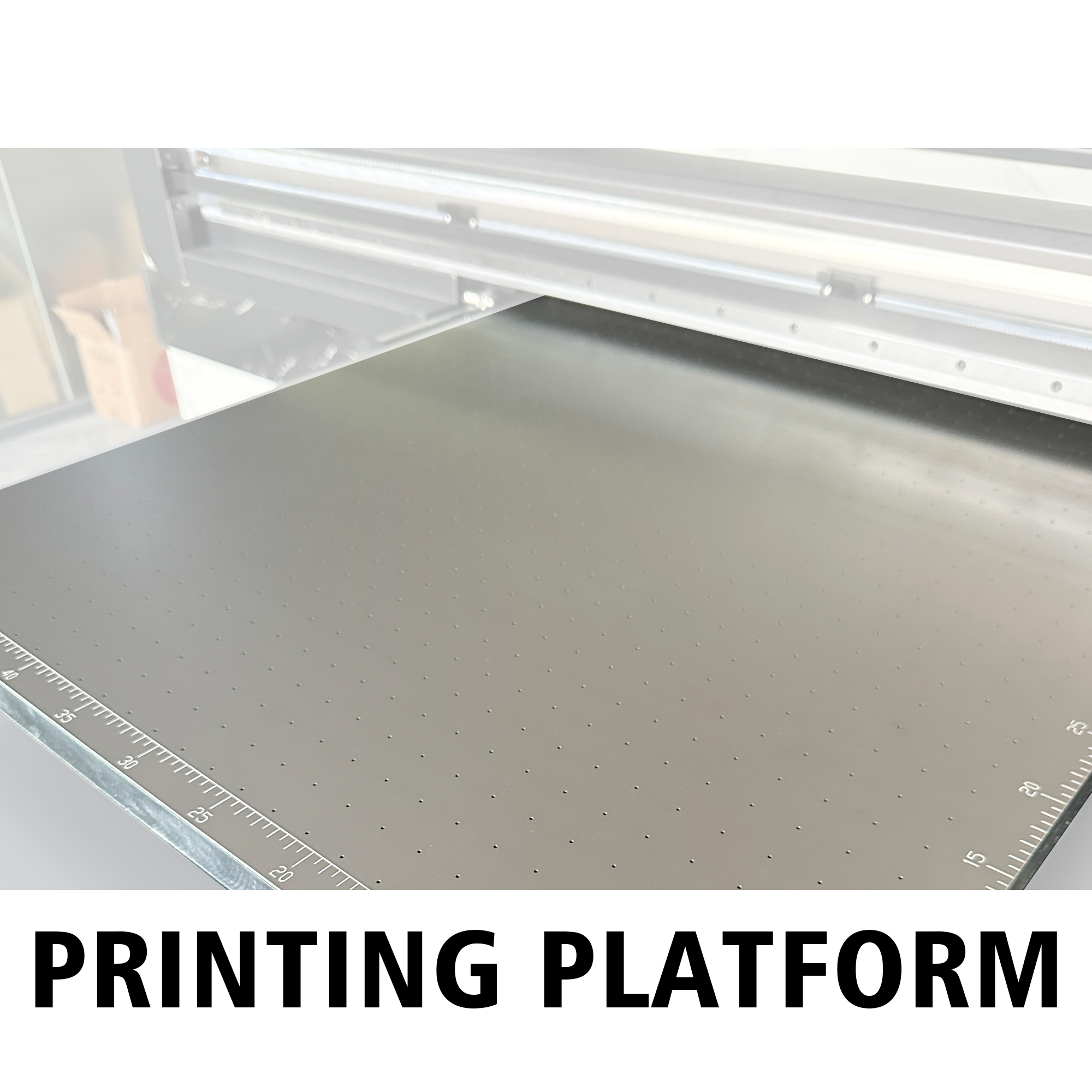

A 60cm*90cm flat platform that can adapt to various materials such as acrylic, glass, and metal. The platform surface is flat and specially treated, which can adapt to various materials and shapes of media. Some platforms have adsorption function, which can firmly fix the medium, avoid medium displacement during the printing process, and ensure printing accuracy.

The device also has high-precision printing capability, which can clearly present details; High printing efficiency, suitable for mass production; Strong material compatibility and diverse application scenarios; It also supports personalized customization and has low maintenance costs, making it a practical printing equipment in fields such as advertising, decoration, and handicraft processing.

Specifications

Model |

6090 3H |

|

printhead |

EPSON i3200U1/xp600 |

|

Quantity of printhead |

3pcs |

|

printing size |

600*900mm |

|

RIP software |

Maintop |

|

Ink color |

CMYK+W+vanish / CMYK lc lm+W+vanish |

|

Max resolution |

720x1440DPI |

|

Printing thickness |

0mm-140mm |

|

printing speed |

xp600 |

6pass: 4m2/h 8pass: 3m2/h 12pass: 2m2/h |

i3200 |

6pass: 12m2/h 8pass: 10m2/h 12pass: 7m2/h |

|

power |

550W |

|

power supply |

110V-220V |

|

operating environment |

15-30℃, 20-30%RH |

|

Ink type |

UV ink |

|

Operating system |

Win7/win8/win10 (64bit) |

|

Image format |

JPG/TIFF/PDF |

|

Diamension |

1760*1550*620mm |

|

Packing size |

1830*1680*850mm |

|

Printing Material |

Glass, plastic, Acrylic metal, wood, etc. |

|

Weight |

280KG |

|

Applications

This UV flatbed machine has a wide range of applicability and can directly print on various materials, including but not limited to acrylic, glass, metal, wood, plastic, ceramic tiles, leather, paper, etc., meeting the diverse printing needs of different industries.

Advantages

( 1 ) High precision printing.

Advanced print head technology and precise mechanical transmission system have achieved high-resolution printing. It can clearly present complex pattern details, small text, natural color transitions, and print realistic and vivid images, providing high-quality output for product identification, decorative painting, and other production.

( 2 ) Efficient production.

UV ink has a quick drying characteristic, which greatly shortens the printing cycle. Compared to traditional printing methods, there is no need to wait for the ink to dry, allowing for continuous and rapid printing, improving production efficiency, especially suitable for batch order production.

( 3 ) Wide material compatibility.

The good adaptability to various materials makes its application scenarios rich and diverse. From the production of advertising signs to the printing of home decoration materials, from the customization of electronic product casings to the processing of handicrafts, they can all perform excellently, providing strong support for enterprises to expand their business scope.

( 4 ) Personalized customization.

It can be printed on media of different shapes and sizes as needed to meet customers' personalized customization needs. Enterprises can easily achieve small batch and multi variety production, provide unique products to the market, and enhance market competitiveness.

FAQ

Q:Can the 6090UV flatbed machine print 3D effects?

A:Sure. By using UV white ink stacking and software control, a certain degree of 3D stereoscopic effect can be achieved. First, use white ink to deposit a three-dimensional shape on the surface of the medium, and then print colored patterns to present a layered 3D effect. It is commonly used to create three-dimensional logos, decorative paintings, etc.

Q:What are the requirements for the usage environment of the device?

A:It should be placed in a dry and well ventilated environment to avoid moisture and excessive dust. It is recommended to maintain the ambient temperature between 15 ℃ and 30 ℃, and the humidity between 30% and 70%. At the same time, it is necessary to ensure that the equipment is well grounded to prevent static electricity from causing damage to the nozzle and circuit.

Q:Do I need to adjust parameters when printing different materials?

A:Yes. Different materials have varying absorbency and surface hardness of ink, requiring adjustments to printing parameters such as nozzle height, ink jet volume, UV curing intensity, and time. The equipment operation manual usually provides reference parameters for common materials, and operators can further adjust them according to the actual printing effect.

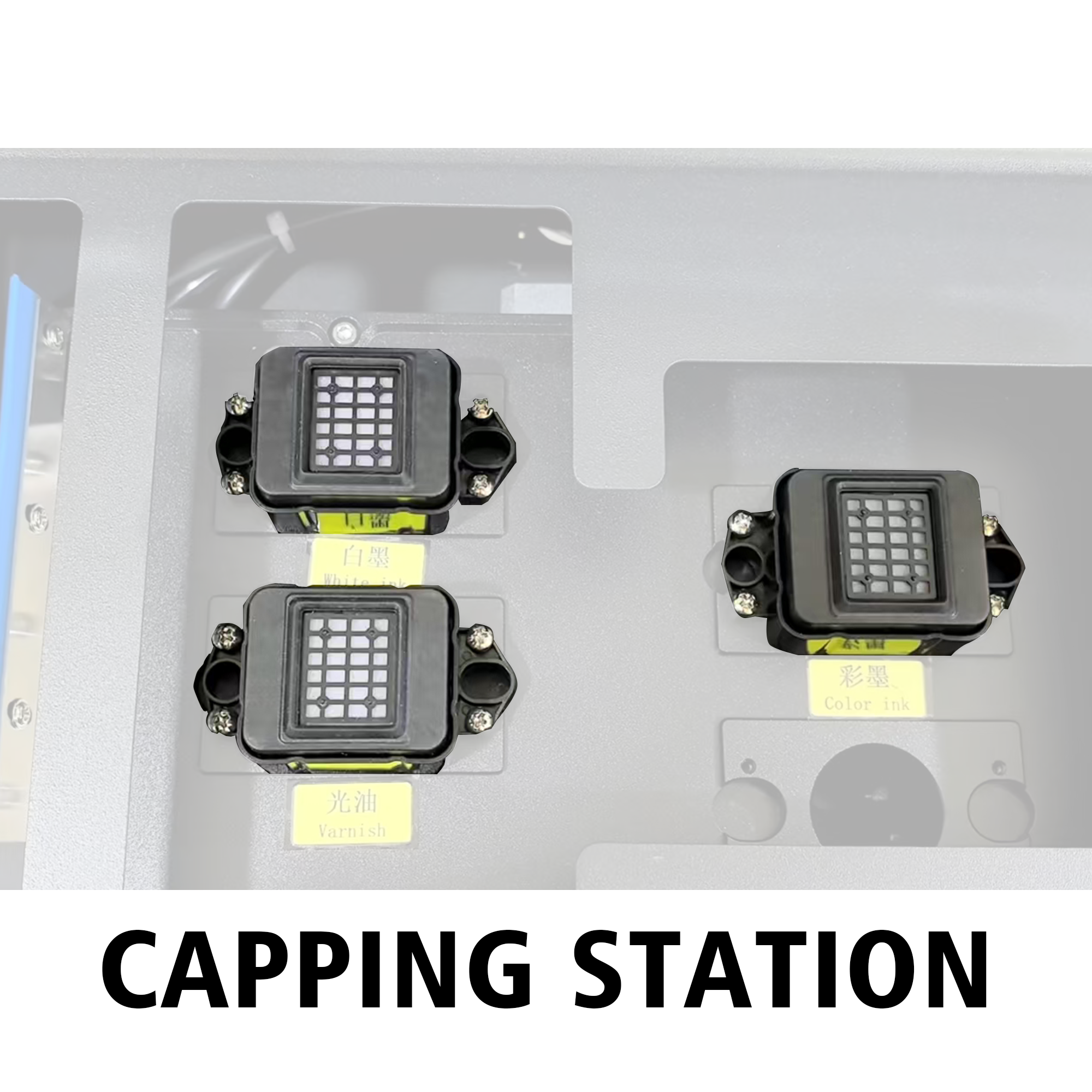

Q:What should I do if the print head is blocked?

A:First, try using the built-in print head cleaning function of the device and clean it with a specialized cleaning solution. If the blockage is severe, the print head can be removed and soaked in cleaning solution for a period of time before cleaning. In daily use, regular cleaning and maintenance of the print head should be carried out to avoid ink drying up and clogging the nozzle due to prolonged disuse of the equipment.

Q:What is the printing speed of the device?

A:Printing speed is affected by various factors, such as printing resolution, pattern complexity, material type, etc. Under standard resolution and ordinary patterns, using common acrylic materials as an example, the printing area can reach several square meters per hour. If the resolution is reduced or simple patterns are printed, the speed will be faster; When pursuing high resolution and complex patterns, the speed will decrease. The specific speed can refer to the equipment technical manual or be tested in actual use.