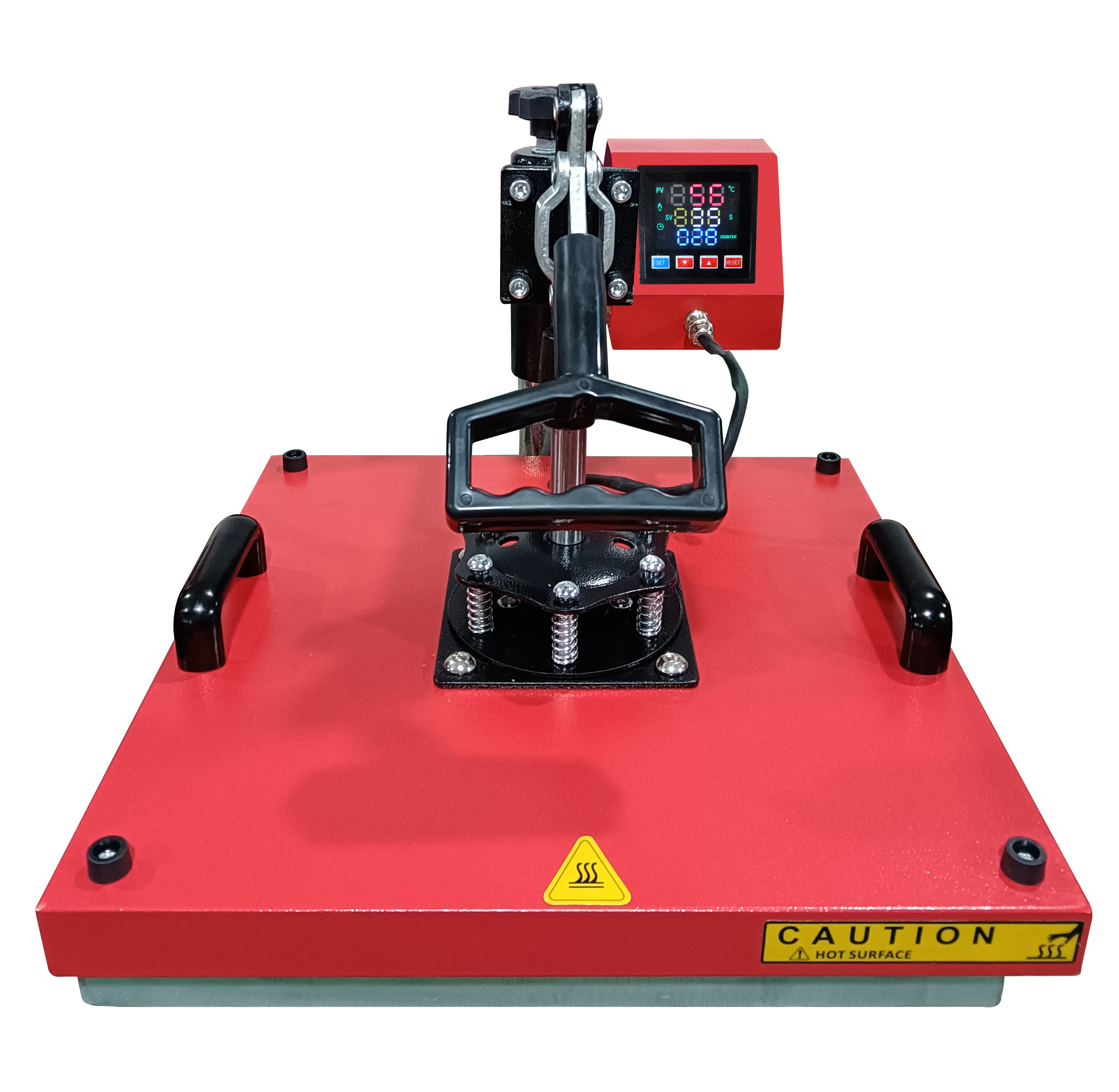

YQ201101 Heat transfer machine

-Item number: YQ201101

- Model: 1100-220 durm, 1200-220 durm, 1600-220 durm

- Machine size: 370*1600*1010mm, 370*1700*1010mm, 370*2100*1010mm

- Heating method: Electric heat pipe heating

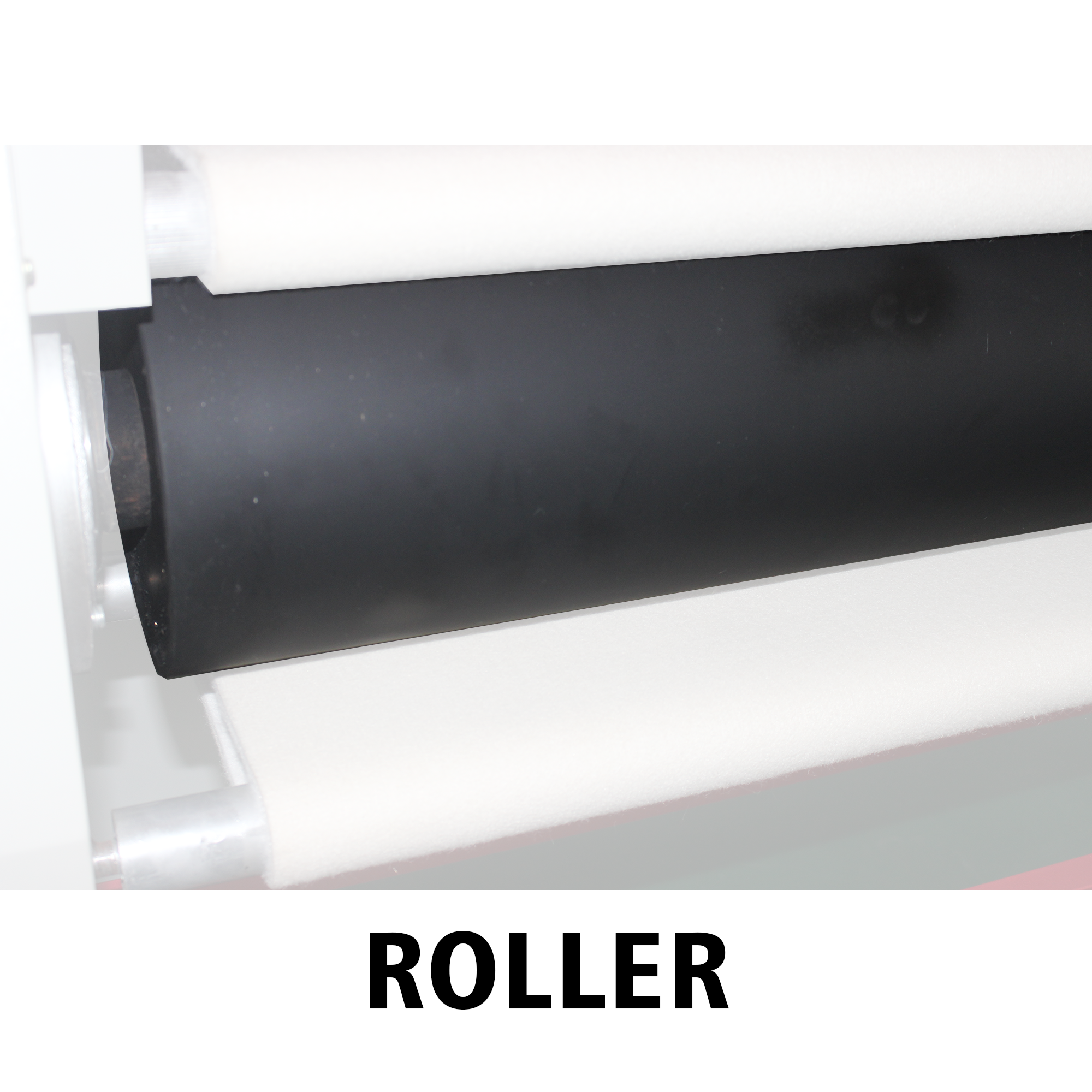

- Diameter of cylinder: 220mm

- The roll surface: Teflon coating

- Power supply: 220V/380V

- Overview

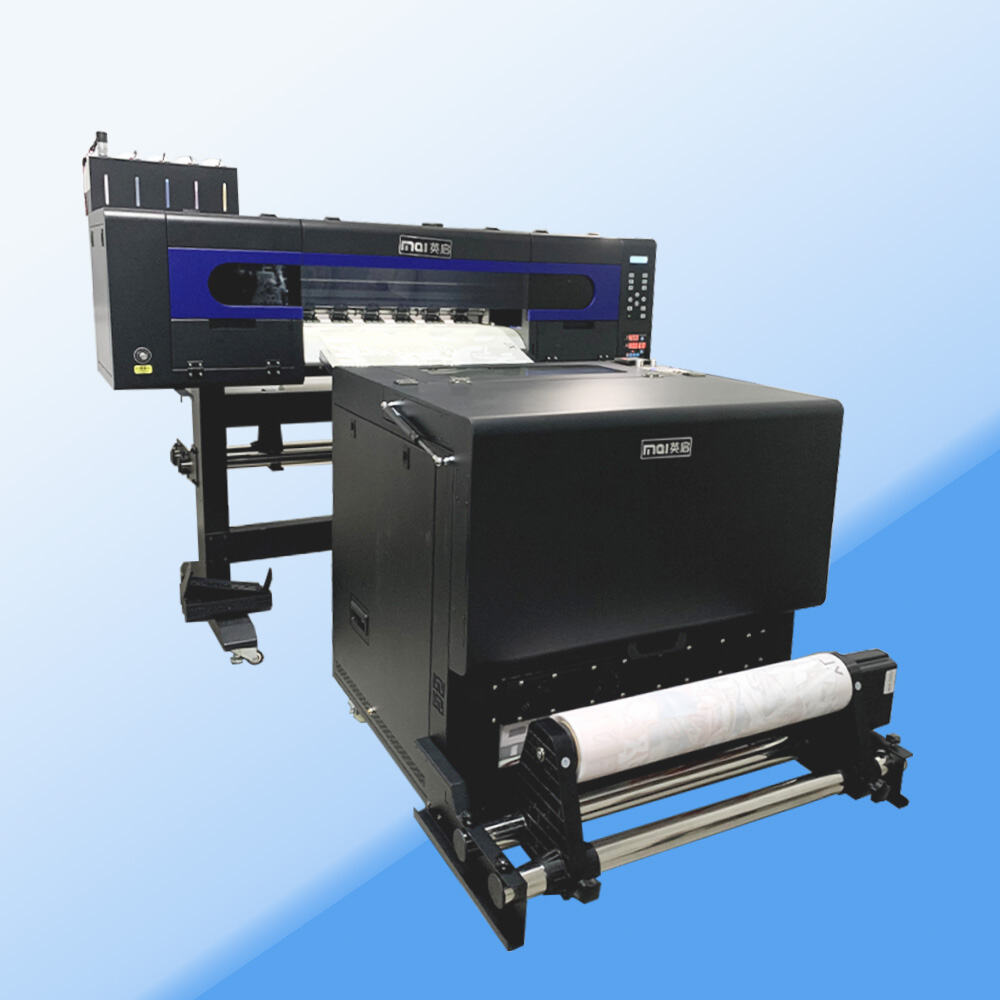

- Recommended Products

Description

This is our simple electric heating heat transfer machine. Our standard sizes are 1.2m, 1.6m, and 1.8m, and we support you in choosing your own voltage. This is an emerging machine on the market that has received high praise since its launch.

The working principle of an electric heating heat transfer machine is to use electric current to generate heat through a heating element, causing the ink on the transfer paper or film to sublime under the action of heat, directly transforming from a solid to a gas, and quickly transferring to the surface of the transfer object under pressure. After cooling, the ink solidifies again, forming strong and delicate patterns, text, or logos on the surface of the object.

Compared with traditional printing methods, heat transfer printing can present more delicate and realistic effects, enhancing the beauty and added value of products.

Specifications

Parameter for 220mm durm heat transfer machine | |||

Model |

1100-220 durm |

1200-220 durm |

1600-220 durm |

Machine size |

370*1600*1010mm |

370*1700*1010mm |

370*2100*1010mm |

Heating method |

Electric heat pipe heating |

||

Diameter of cylinder |

220mm |

||

The roll surface |

Teflon coating |

||

Power supply |

220V/380V |

||

Heating power |

4.8KW |

5.2KW |

6.6KW |

Total power |

4.9KW |

5.3KW |

6.7KW |

Speed |

20-80m/hour |

||

Temperature range |

30-250 degree |

||

Width of Blanket |

1120mm |

1220mm |

1620mm |

Heat transfer material width |

1000mm |

1100mm |

1500mm |

Blanket adjustment form |

Manual adjustment |

Manual adjustment |

Manual adjustment |

Machine weight |

120kg |

130kg |

180kg |

Packing size |

1.79*0.59*0.6m |

1.89*0.59*0.6m |

2.2*0.59*0.6m |

Applications

It can be widely applied to various materials such as paper, plastic, metal, ceramics, wood, etc. Suitable for the production of various product labels, packaging, decorations, souvenirs, etc., covering multiple industries such as advertising, printing, gifts, clothing, etc.

Advantages

( 1 ) Efficient transfer printing.

Electric heating elements can quickly heat up, greatly reducing preheating time. At the same time, a stable heating and pressure system enables efficient transfer process, enabling the completion of a large number of transfer tasks in a short period of time and improving production efficiency.

( 2 ) Precise control.

The advanced control system can accurately adjust temperature, time, and pressure to ensure that each transfer can achieve the best results. Whether it's complex patterns or tiny text, they can be clearly and accurately transferred to the surface of objects, reducing waste rates.

( 3 ) High quality effect.

The transferred pattern has bright colors, high saturation, good adhesion and wear resistance. Compared with traditional printing methods, heat transfer printing can present more delicate and realistic effects, enhancing the beauty and added value of products.

( 4 ) High quality effect.

The concise and clear control panel and easy to understand operation process enable operators to quickly get started. Even personnel without professional experience can proficiently master the operation methods of equipment after simple training.

( 5 ) Environmental protection and energy conservation.

Adopting electric heating method is cleaner and more environmentally friendly compared to traditional heating methods such as gas heating, reducing exhaust emissions. Meanwhile, an efficient heating system can effectively reduce energy consumption and save production costs.

FAQ

Q:What colors of patterns can be transferred by an electric heating heat transfer machine?

A:The heat transfer machine can transfer almost any color of pattern, depending on the color of the transfer paper used. By combining and blending different colors, various colorful pattern effects can be achieved.

Q:What should be noted when transferring objects of different materials?

A:For objects of different materials, it is necessary to adjust the appropriate temperature, pressure, and time parameters during transfer printing. For example, the paper material is relatively thin, the transfer temperature should not be too high, and the pressure should be appropriately reduced; Metal materials require higher temperatures and greater pressure to ensure that ink can fully adhere. In addition, attention should be paid to the cleanliness and flatness of the object surface to avoid affecting the transfer effect due to surface impurities or unevenness.

Q:What should I do if the device experiences unstable temperature?

A:First, check if the heating element is damaged. If it is damaged, it should be replaced in a timely manner. At the same time, check if the temperature sensor is working properly, and if there is a malfunction, calibrate or replace it. In addition, check whether the parameter settings of the control system are correct to ensure that the temperature control range is reasonable. If the above methods still cannot solve the problem, please contact our after-sales service personnel.

Q:What should I do if the transferred pattern is prone to color fading?

A:If the transferred pattern is prone to color fading, it may be caused by the following reasons. One issue is improper temperature, pressure, or time settings during transfer printing, which may result in insufficient ink adhesion to the surface of the object. In this case, it is necessary to readjust the parameters for transfer printing; Secondly, low-quality transfer materials were used, and it is recommended to replace them with high-quality transfer paper or film; The third issue is improper surface treatment of the transferred object. Proper cleaning, polishing, and other pre-treatment can be carried out on the surface of the object before transfer to enhance the adhesion of the ink.

Q:What aspects should be paid attention to in the maintenance of equipment?

A:Regularly clean the surface of the equipment and the transfer platform to prevent dust and impurities from accumulating and affecting the transfer effect. Check if the connecting components of the heating element, pressure system, and control system are loose, and tighten them promptly if they are loose. Regularly conduct performance testing on heating elements to ensure their normal operation. At the same time, according to the requirements of the equipment manual, lubricate and maintain the transmission components to extend the service life of the equipment.