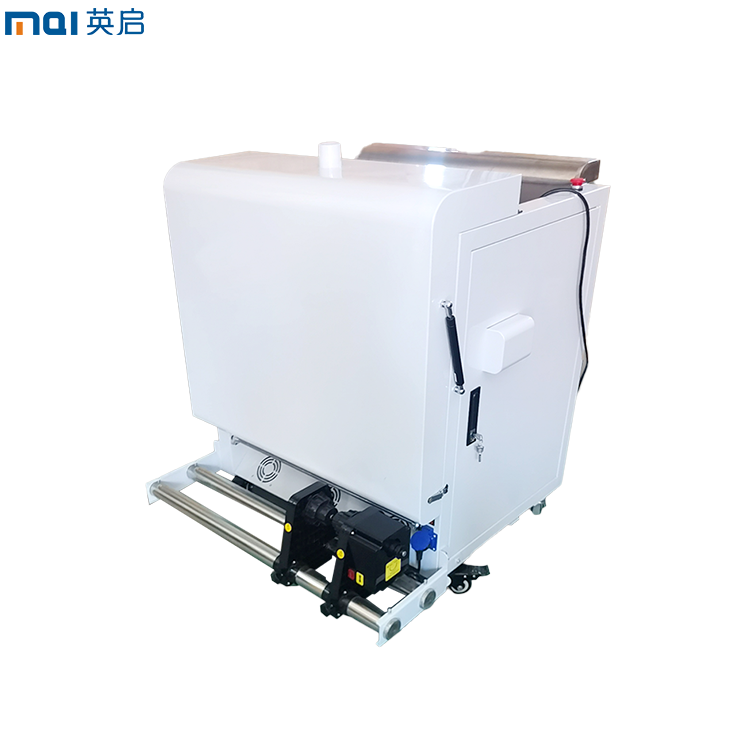

A3 DTF printer(2pcs)

- Model: 300C

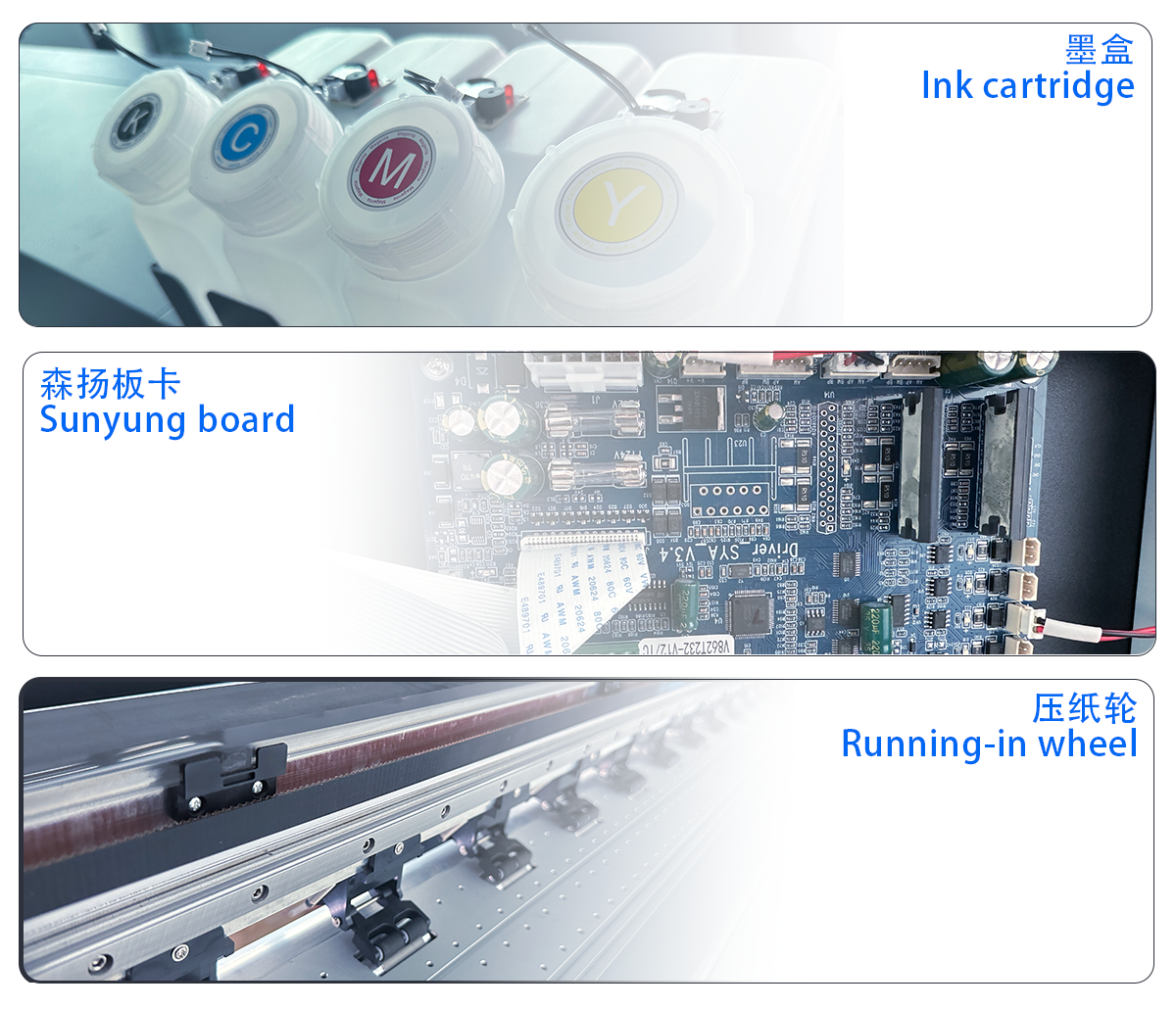

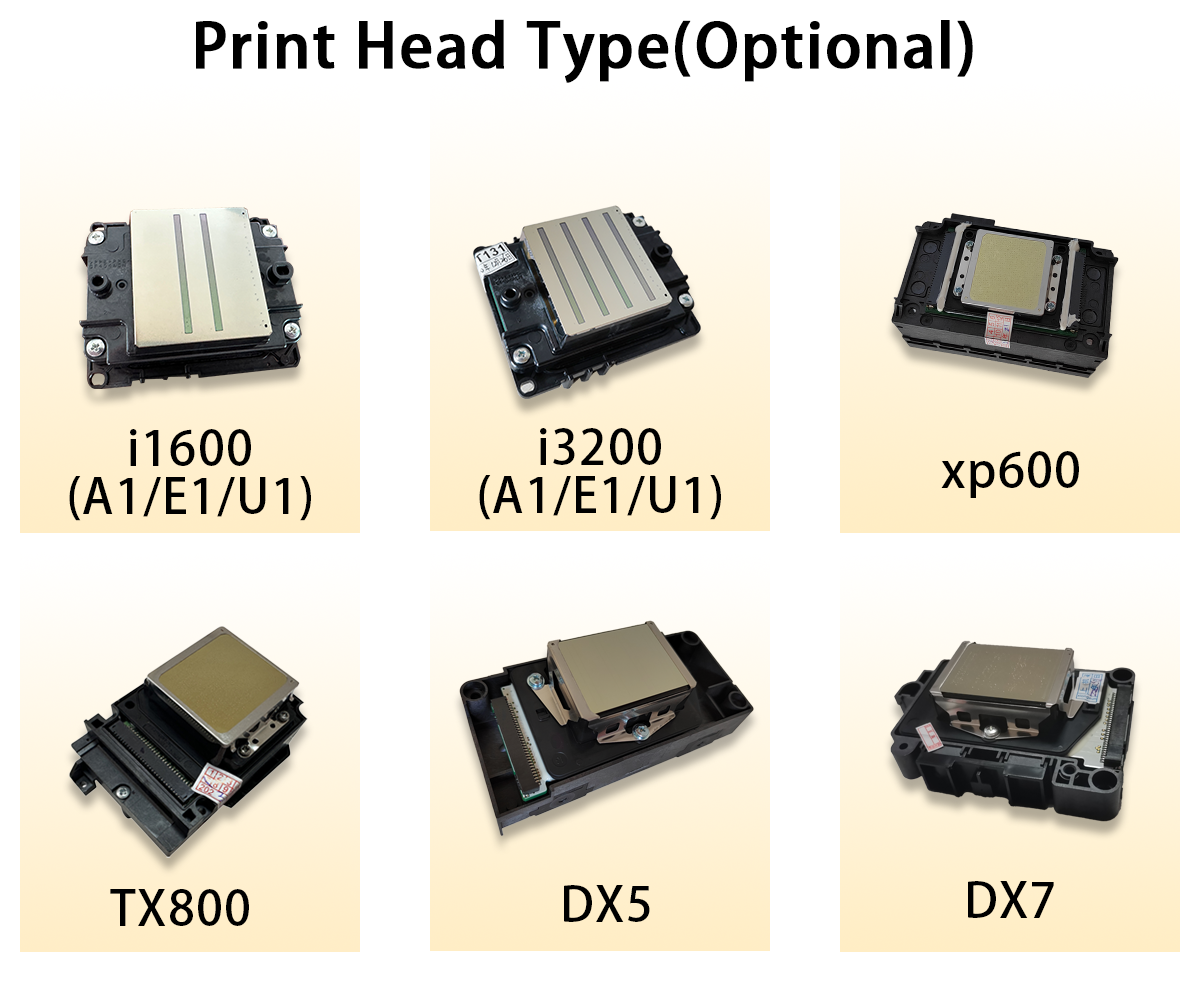

- Printhead: EPSON XP600 printhead

- Quantity of printhead: 2pcs

- Print width: 300mm

- Color management: ICC

- Heating system: front, middle and back

- Print resolution: 400*8=3200DPI

- Printable media: PET film

- Software: Maintop 6.1

- Ink: DTF ink

- Color: CMYK+W 300ml/bottle

- Overview

- Recommended Products

Description

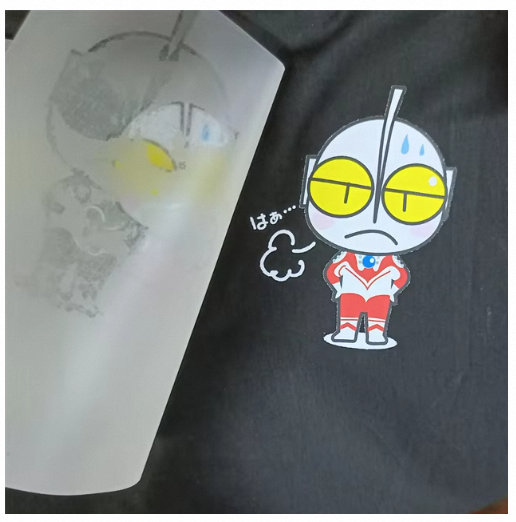

This 30cm DTF printer is equipped with two XP600 print heads, using Hansen board and Maintop software, and is currently the most advanced white ink hot stamping technology.

Firstly, the dual XP600 print head accurately lays special ink containing white pigment and colorful ink on the transfer paper based on the pattern information, constructing a complete and detailed pattern prototype. Subsequently, with the help of high-temperature and high-pressure hot stamping equipment, under specific temperature and pressure conditions, the ink molecules on the transfer paper quickly become active, penetrate and tightly bond with various fabric fibers.

Especially white ink, with its high coverage, can also present pure and bright white patterns on dark fabrics, allowing the entire hot stamping pattern to be clearly and vividly displayed on fabrics with different backgrounds, breaking through the limitations of traditional hot stamping printing on dark fabrics and greatly expanding the possibilities of hot stamping creation.

Specifications

Parameter for DTF printer | ||

Model |

300C |

|

printhead |

EPSON XP600 printhead |

|

quantity of printhead |

2pcs |

|

print width |

300mm |

|

Color management |

ICC |

|

Heating system |

front, middle and back |

|

Print resolution |

400*8=3200DPI |

|

Printable media |

PET film |

|

Software |

Maintop 6.1 |

|

Ink |

DTF ink |

|

Color |

CMYK+W 300ml/bottle |

|

Print speed |

4pass |

6m2/h |

6pass |

4m2/h |

|

Operate system |

Windows 7/10 |

|

interface |

Gigabit interface |

|

Power supply |

220V 50HZ |

|

Machine size |

910*650*510mm |

|

Packing size |

0.99*0.63*0.67=0.31CBM |

|

New weight |

60KG |

|

Gross weight |

83KG |

|

Parameter for POWDER SHAKER | ||

Model |

A3 powder shaker |

|

Working width |

0-300mm |

|

Suitable material |

pet film |

|

Powder control |

Shake powder control, dusting control, direction and quantity control. |

|

Shake powder Assist |

Upper drying and curing, cold air cooling function, automatic take up the material |

|

power supply |

220V, 12A, 2200W |

|

machine size |

860*660*620mm |

|

packing size |

07*0.61*0.76m=0.265CBM |

|

net weight |

35KG |

|

gross weight |

50KG |

|

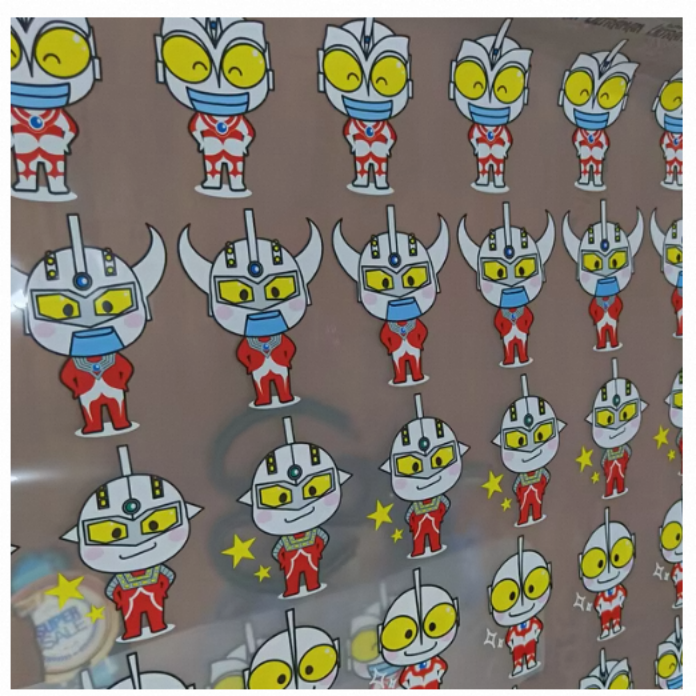

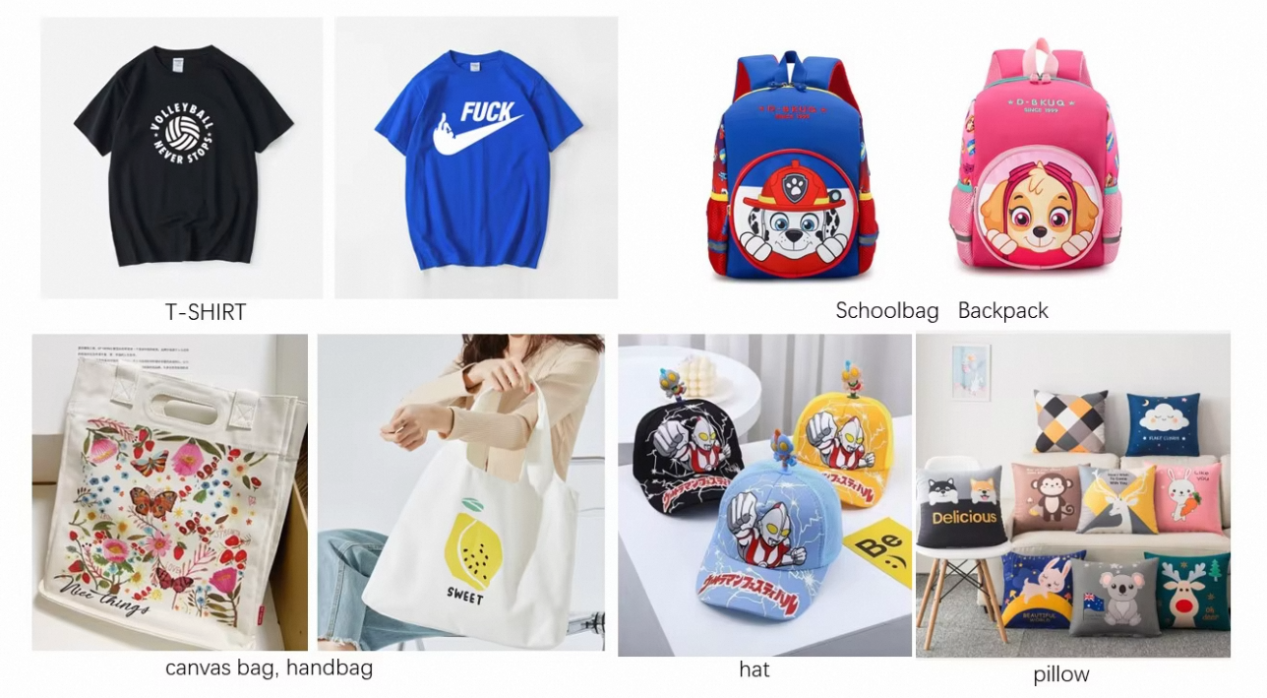

Applications

It is widely used for personalized hot stamping customization of various textile products such as clothing, home textiles, luggage, etc., to meet the needs of different customers.

Advantages

( 1 ) Excellent picture quality.

High resolution:

The printed images and text have clear and sharp edges, rich details, and can present both fine patterns and tiny text clearly, meeting the high quality requirements of users.

High color reproduction:

Accurately reproducing the colors of the original image, with high color saturation and appropriate contrast, the printed image is vivid and realistic in color, giving a strong visual impact.

Delicate color transition:

When printing gradient colors or images with rich color tone layers, it can avoid color discontinuity or stripe phenomenon, make color transition natural and smooth, and present a softer and more realistic picture effect.

( 2 ) Wide adaptability to various media.

Common fabric media:

capable of high-quality hot stamping printing on fabrics made of pure cotton, linen, silk, synthetic fibers, and other materials. Whether it's soft T-shirt fabric or uniquely textured canvas, the printer can firmly transfer patterns onto the fabric surface while maintaining good color adhesion and wash resistance.

Special fabric media:

It can also support hot stamping of some special fabric media, such as leather, denim, functional fabrics, etc. For leather products, exquisite patterns can be printed on their surface to increase the added value of the product; Hot stamping on denim can create a fashionable and personalized denim clothing series; For functional fabrics, such as breathable fabrics for sportswear and waterproof fabrics for outdoor equipment, printers can also ensure that patterns adhere firmly and achieve excellent results without affecting the original function of the fabric.

( 3 ) Efficient printing.

Faster printing speed:

With the premise of ensuring high-quality printing, it has a relatively fast printing speed. Its printing speed can meet daily production needs and effectively improve work efficiency.

Good stability in continuous printing:

The stable mechanical structure and control system ensure the stability of the printer during long-term continuous printing processes. The key components such as the print head and motor can operate continuously and efficiently, avoiding problems such as overheating and lagging, ensuring the smooth progress of printing tasks, reducing downtime caused by equipment failures, and improving production efficiency.

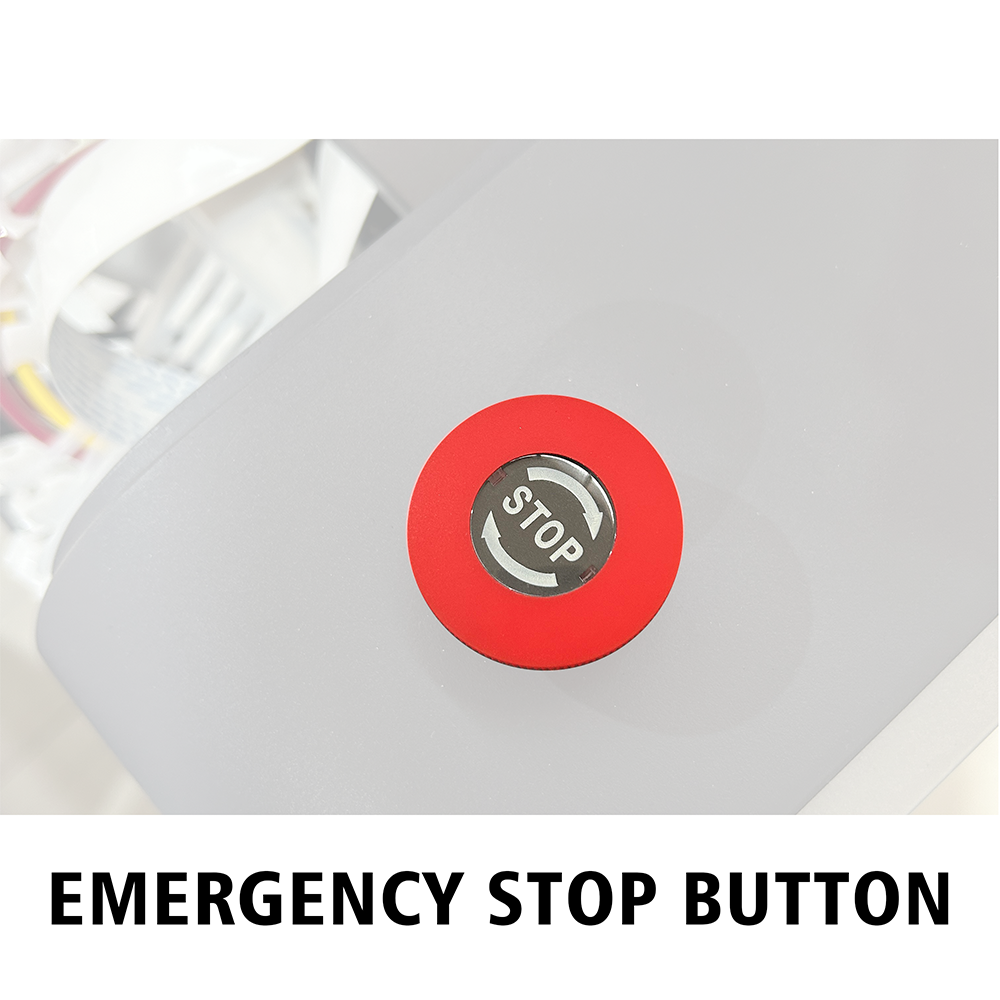

FAQ

Q:What should I do if the print head of the printer is blocked?

A:The printer is equipped with an automatic cleaning and ink scraping system. When there is a slight blockage in the print head, the automatic cleaning function can be activated through the printer's control panel. This function uses cleaning solution to clean the print head and usually solves the blockage problem. If the blockage still cannot be resolved after automatic cleaning, it may be due to severe blockage of the print head. In this case, we need to contact our after-sales technical personnel for handling. After sales technicians will use more professional cleaning methods, such as soaking and cleaning with specialized print head cleaning solution. It is not recommended for users to disassemble the print head for cleaning on their own to avoid damaging the print head.

Q:Can it be printed on media of different thicknesses?

A:This printer can print on media within a certain thickness range. When printing media of different thicknesses, it is necessary to adjust the relevant parameters of the printer appropriately according to the thickness of the media, such as the height of the print head, pressure, etc., to ensure that the appropriate distance is maintained between the print head and the media, and to ensure the printing effect. The specific adjustment method can refer to the printer's operation manual or consult the after-sales technical personnel.

Q:How long is the warranty period for the printer?

A:In general, the entire printer comes with a one-year warranty service, and core components such as print heads, motors, control systems, etc. are also covered by a one-year warranty. During the warranty period, if the equipment malfunctions due to non-human factors, the manufacturer will provide free repair services. However, it should be noted that users should operate and maintain the equipment correctly according to the printer's user manual, otherwise it may affect warranty rights. If the device exceeds the warranty period, users can still contact after-sales technicians for repairs, but they will need to pay the corresponding repair fees.