Reklamcılıkta UV Düz Yataklı Yazıcı Uygulamalarını Anlamak

UV Düz Yataklı Yazıcıların Reklam Üretimini Nasıl Devrimleştirdiği

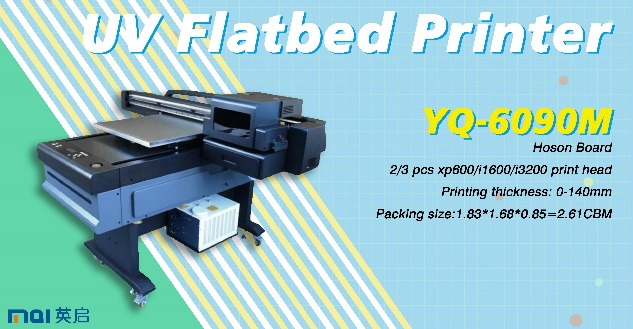

Düz yüzeyli UV yazıcılar, kalınlığı 10 santimetreye kadar olan katı malzemelere doğrudan baskı yapabildikleri için reklamların üretim şeklini değiştiriyor. Geleneksel yöntemler birkaç farklı üretim aşaması gerektiriyordu ancak bu yeni makineler sayesinde firmalar ahşap levhalar, akrilik paneller ve hatta cam yüzeyler gibi ürünleri tek seferde markalayabiliyor. Bunları öne çıkaran şey nedir? Mürekkep UV ışık altında anında kuruyor, böylece kuruması için beklemek gerekmiyor. Geçen yıl SGIA'nın sektör raporlarına göre bu durum üretim süresini yaklaşık %70 oranında kısaltıyor ve bu özellikle sıkı teslim tarihlerinde büyük bir avantaj sağlıyor. Ayrıca detaylı çalışmaya gelince; bu yazıcılar ±0,1 mm doğruluk sağlayabiliyor, yani karmaşık tasarımlarda bile metinler ve görseller net kalıyor. Üstelik yeni nesil LED lambalar eski cıva buharlı sistemlere kıyasla %35 daha az enerji tüketiyor ve bu da hem bütçeye hem de çevreye daha dost olmalarını sağlıyor.

Malzeme Çeşitliliğinin Özel İşaretlerdeki Rolü

Günümüzde başarılı reklamcılığın ardındaki gizli formül, mesajlarımızı nereye yerleştirdiğimizle ilgilidir. UV düz yataklı yazıcılar artık her tür yüzeyi işleyebilir. Elleriyle dokunan kişilerde harika bir his uyandıran fırçalanmış metal tabelalar ya da dikkat çeken oymalarla süslenmiş ahşap vitrinler düşünün. Aynı zamanda açılır kapanır mağazalar için 3 mm akrilik paneller ya da geçici kurulumlar için PVC köpük levhalar gibi hafif malzemelerle de mükemmel sonuçlar verir. Sislenme cam ekranlardan geri dönüştürülmüş malzemelerle üretilen çevre dostu plastik seçeneklere kadar sıcaklık değişimlerine duyarlı malzemeler için de uygundur. Markalar bu esnekliği seviyor çünkü fuarlarda iç mekânda kurulum yaparken, araçların tamamını kaplarken ya da sekiz kat yüksekliğindeki binalara devasa kurulumlar oluştururken mesajlarını tutarlı şekilde koruyabiliyorlar. Pazarlamalarında farklı malzemeleri bir araya getiren etkinlik organizatörleri ilginç bir şey fark ettiler: insanlar bu etkinliklerde gördüklerini, her şeyin sıradan vinil olduğu zamanlara göre yaklaşık %40 daha iyi hatırlıyor. Zaten beynimizin birden fazla duyuyla etkileşime giren şeylere daha çok bağlanması mantıklı bir durum.

Neden Sert Malzemeler Dış Reklamlarda Geleneksel Medyaya Göre Daha İyi Performans Gösterir

UV teknolojisiyle basılan sert malzemeler, esnek medyaya göre çevresel etkenlere 4 kat daha uzun dayanır:

| Faktör | Esnek Medya | UV ile Basılmış Sert Medya |

|---|---|---|

| Solarmaya dirençli | 6–12 ay | 3–5 yıl |

| Darbe Toleransı | Düşük | 150 psi ezilme dayanımı |

| Kurulum Başına Getiri (ROI) | $0,18\/sq.ft | $2,70\/sq.ft |

Laminelemenin kaldırılması, mevsimsel sıcaklık dalgalanmalarında %95 renk doğruluğunu korurken malzeme maliyetlerini %22 oranında düşürür.

Yüksek Etki Gücüne Sahip Reklamlar İçin Sert Malzemeler: Ahşap, Metal ve Cam

UV düz yataklı yazıcılar, yapısal bütünlük ve tasarım esnekliği nedeniyle dış mekân promosyon kurulumlarının %68'ini oluşturan sert malzemeleri, çevresel streslere karşı dayanıklı çarpıcı reklam parçalarına dönüştürmede üstündür.

Rustik ve Çevre Dostu Reklam Panoları için Ahşap Üzerine Baskı

Bambu ve geri kazanılmış kereste gibi ahşap altlıklar, çevre bilincine sahip hedef kitleye yönelik markalar için sürdürülebilir seçenekler sunar. UV ile sertleşen mürekkepler gözenekli yüzeylere sorunsuz bir şekilde yapışır ve el sanatları pazarları ile butik mağaza vitrinleri için vintage tarzında tabelalar oluşturur.

UV Düz Yataklı Baskı İçin Metal Malzemeler – Dayanıklılık ve Tasarımın Buluştuğu Nokta

Alüminyum kompozitler ve fırçalanmış metal paneller, yoğun trafiğin yaşandığı alanlar için hava koşullarına dirençli reklam çözümleri sunar. 2023 yılında yapılan bir altlık performans çalışması, metal bazlı ekranların UV ışığı altında renk sadakatini vinil kaplamalara göre %40 daha uzun süre koruduğunu ortaya koymuştur ve bu durum onları ulaşım merkezleri ile bina cephe uygulamaları için ideal hale getirir.

Perakende ve Sergi İşaretlerinde Premium Arka Planlar İçin Cam Yüzeyler

Dondurulmuş veya temperli camlar, UV teknolojisiyle basılarak lüks ürün tanıtımları ve müze kurulumları için ışıl ışıl ekranlar oluşturur. Gözeneksiz yüzey, parfüm tezgahlarının arkasında aydınlatmalı olarak veya mimari yönlendirme sistemlerinde kullanılmak üzere 1200 dpi'ye kadar keskin grafiklere olanak tanır.

Sert Malzemelerde Mürekkep Yapışması İçin Yüzey Hazırlama Teknikleri

Kritik adımlar arasında ahşap liflerinin 180 zımpara ile pürüzsüz hale getirilmesi, metal yüzeylerin izopropil alkolle yağ giderilmesi ve gözeneksiz camlara UV özel primerlerinin uygulanması yer alır. Bu yöntemler, işlenmemiş yüzeylere kıyasla mürekkep yapışma gücünü 3,1 kat artırır (SGIA 2023).

İç Mekân ve Dış Mekân UV Basılı Reklamlar İçin Malzeme Seçimini En İyileştirme

Uzun Vadeli Dış Mekân Reklamcılığı İçin Hava Koşullarına Dayanıklı Malzemeler

Dış mekân UV baskılı reklamlar söz konusu olduğunda, güneş ışığına, yağmura ve sıcaklık değişimlerine dayanabilen malzemeler bulmak oldukça önemlidir. Alüminyum kompozit panel (ACM) ve UV ile sertleşen vinil levhalar bu amaç için oldukça uygundur. Bu malzemeler, renklerin tüm gün boyu güneşte kalsa bile yaklaşık beş ila yedi yıl tazeliğini korumasını sağlar. Son yapılan bazı testler, 18 ay boyunca dış mekânda bırakılan ACM destekli baskıların orijinal renk yoğunluğunun yaklaşık %98'ini koruduğunu göstermiştir ve bu performans, geleneksel PVC'yi neredeyse üçte bir oranında geçmektedir. Daha çevre dostu bir seçenek arayanlar için, UV düz yüzey baskı teknolojisiyle harika çalışan emprenye edilmiş ahşap alternatifleri de mevcuttur. Sonuç? Zamanla doğal bir şekilde eskiyen ancak çarpılmayan veya böcekler tarafından aşınmayan tabelalar.

Düşük Uçucu Organik Bileşikli, Toksik Olmayan Malzemeler Kullanılarak İç Mekân Görüntüleme Çözümleri

Kapalı alanlarda, hava kalitesi dokunma hissi kadar önemlidir. Bu ortamlar için akrilik paneller ve geri dönüştürülmüş köpük levhalar oldukça popüler hale gelmiştir. Bu malzemeler çizilmeye karşı dirençli olup renkleri çok hassas bir şekilde baskılayan UV yazıcılara uygundur. Pazar araştırmacıları son zamanlarda perakende vitrin tasarımında formaldehit içermeyen MDF'nin yaygınlaştığını belirtiyor. Bu malzeme ne ile öne çıkıyor? UV baskısından sonra düzgün bir yüzey sunarken, normal kontrplaktan çok daha az zararlı kimyasal salgılar. Yaklaşık olarak %75 daha az uçucu organik bileşik (VOC) salınımı söz konusu bu durumda ve bu da kapalı mekânlarda geçirilen sürenin daha sağlıklı olmasını sağlar.

Veri Analizi: Reklamverenlerin %78'i Dayanıklılık İçin UV Baskılı Sert Ortamları Tercih Ediyor (Kaynak: SGIA 2023)

2023 SGIA raporu, cam ve metal gibi sert malzemelerin UV ile basılan dış mekân reklamlarının %82'sini oluşturduğunu ve esnek alternatiflere göre 3,1 kat daha uzun dayandığını ortaya koyuyor. Bu tercih, çözücü bazlı baskıya kıyasla hava koşullarına bağlı bozulmayı %67'ye varan oranlarda azaltan, UV ile sertleşen mürekkeplerin gözeneksiz yüzeylerle moleküler bağ kurmasından kaynaklanmaktadır.

Malzeme Çeşitliliği ve Reklam Yeniliğinin Geleceği

Kavramdan Gerçekliğe: UV Düz Yatak Yazıcı Teknolojisi ile Hızlı Prototipleme

Günümüzde UV düz yataklı yazıcılar dijital tasarımları oldukça hızlı bir şekilde gerçek prototiplere dönüştürebilir, bazen sadece birkaç saat içinde. Bu, reklamverenlerin fikirlerinin kampanya materyalleri üzerinde nasıl görüneceğini baskıyı yapmadan çok önce görebilmeleri anlamına gelir. Artık dış kaynaklı numuneler için haftalarca beklemek gerekmiyor. Tasarımcılar farklı malzemeler üzerinde renkleri kontrol edebilir, erken aşamada sorunları tespit edebilir ve maliyetleri artırarak değişiklikler yapabilir. Bu yazıcıları bu kadar kullanışlı kılan şey, tüm türde yüzeylerle çalışabilme yetenekleridir. Hem yumuşak 3D baskılı plastikler hem de lazerle kesilmiş keskin kenarlı akrilikler dahil her şeyle başa çıkabilirler. Sonuç? Mağazalarda ya da etkinliklerde müşterilerin nihayetinde alacağı ürünlere gerçekten benzeyen ve onlar gibi hissettiren prototipler.

Karşılaştırmalı Analiz: Reklam Materyalleri İçin UV Düz Yataklı Baskı ve Çözücü Bazlı Baskı

UV düz yataklı baskı, çözücü bazlı alternatiflere göre üç temel alanda daha üstün performans gösterir:

| Faktör | UV Düz Yataklı Baskı | Çözücü Bazlı Baskı |

|---|---|---|

| Malzeme uyumluluğu | Sert altlık malzemeleriyle çalışır | Esnek ortamlarla sınırlıdır |

| Kürlenme Süresi | LED maruziyetiyle anında kurur | Kurutma için gereken saat |

| Çevresel Etki | Düşük uçucu, enerji verimli | Yüksek uçucu emisyonları |

Isıya duyarlı malzemelerin bükülmesinin olmaması, UV yazımı boyutlu işaretlemeler için ideal hale getirir, buna karşılık çözücü yazıcılar vinil ve kumaş uygulamalarının ötesinde zorlanır.

Gelecek Trendi: Dijital Tasarım ile Akıllı Entegrasyon ve Alt Tabaka Çeşitliliği

Yeni iş akışı yöntemleri, parametrik tasarım araçlarını UV düz yatak yazıcılara birleştirerek grafiklerin üzerine basıldıkları şeye göre otomatik olarak uyarlanmasını sağlıyor. 2023 yılına ait sektörel verilere göre, birçok reklamveren, seramik yüzeylere uygulanan iletken mürekkep ile plastik malzemelere yerleştirilmiş NFC çiplerinin bir araya getirildiği, UV baskının neredeyse her yüzeyi işleme yeteneğiyle çok daha iyi çalışan bu tür karışık medya ekranlarını talep etmeye başlıyor. Bu teknolojinin dijital panolardan dokunulduğunda tepki verenlere kadar, mağaza vitrinlerinden sergilenen ürüne göre gerçekten şekil değiştirebilenlere kadar her yerde karşımıza çıktığını görüyoruz. Belirli özel malzemelerle ilgili hâlâ sınırlamalar olsa da, potansiyel uygulamalar hızla birden fazla sektörde yayılmaya devam ediyor.

SSS

Reklamcılıkta UV düz yatak yazıcıların kullanılmasının temel faydaları nelerdir?

UV düz yataklı yazıcılar, çeşitli kalın ve katı malzemelere doğrudan baskı yapma imkanı sunar ve üretim aşamalarını ve süresini %70'e varan oranlarda azaltır. Detaylı çalışmalarda ±0,1 mm hassasiyet sağlar ve ahşap, metal, cam gibi farklı yüzeyler üzerinde yüksek etki yaratan ve çok yönlü reklam çözümleri sunar.

Dış mekân reklamlarında neden sert altlıklar tercih edilir?

Sert altlıklar, esnek ortamlardan daha uzun dayanır ve çevresel etkenlere karşı dört kat daha uzun süre direnç gösterebilir. Üstün solmaya karşı direnç, darbe dayanımı sağlar ve her kurulumda daha iyi bir yatırım getirisi sunar.

UV düz yataklı baskı, çözücü bazlı baskıyla karşılaştırıldığında nasıl bir avantaj sağlar?

UV düz yataklı baskı, daha geniş bir altlık yelpazesi destekler, LED ışıkla anında kürlenme sağlar ve çözücü bazlı baskıya kıyasla düşük VOC emisyonu ile daha çevre dostudur.

İç mekân UV baskılı reklamlar için hangi malzemeler idealdir?

Akrilik paneller ve geri dönüştürülmüş köpük levhalar, çizilmeye karşı dirençleri ve toksik olmamaları nedeniyle iç mekân reklamları için popülerdir; bu da kapalı ortamlarda daha iyi hava kalitesini destekler.

UV düz yataklı yazıcılar hızlı prototipleme için uygun mudur?

Evet, UV düz yataklı yazıcılar dijital tasarımları hızlıca somut prototiplere dönüştürebilir ve reklamverenlerin seri basımdan önce fikirlerini gerçek malzemeler üzerinde görme ve test etme imkânı sunar.

İçindekiler

- Reklamcılıkta UV Düz Yataklı Yazıcı Uygulamalarını Anlamak

- Yüksek Etki Gücüne Sahip Reklamlar İçin Sert Malzemeler: Ahşap, Metal ve Cam

- İç Mekân ve Dış Mekân UV Basılı Reklamlar İçin Malzeme Seçimini En İyileştirme

- Malzeme Çeşitliliği ve Reklam Yeniliğinin Geleceği

-

SSS

- Reklamcılıkta UV düz yatak yazıcıların kullanılmasının temel faydaları nelerdir?

- Dış mekân reklamlarında neden sert altlıklar tercih edilir?

- UV düz yataklı baskı, çözücü bazlı baskıyla karşılaştırıldığında nasıl bir avantaj sağlar?

- İç mekân UV baskılı reklamlar için hangi malzemeler idealdir?

- UV düz yataklı yazıcılar hızlı prototipleme için uygun mudur?