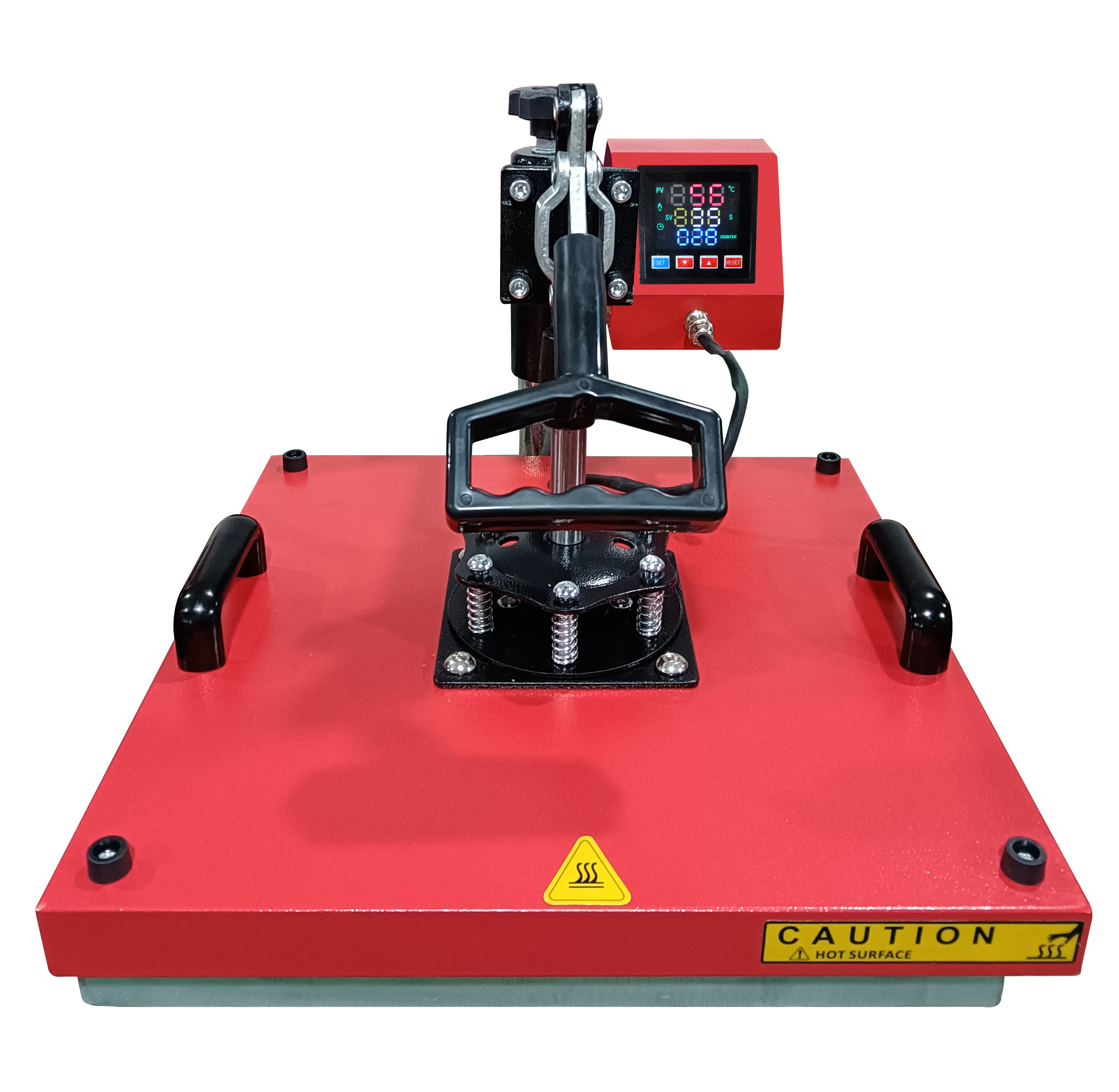

Electric type heat transfer machine

- Item No.YQ201107

-

Model:YQ-1222ZT-EL/YQ-1622ZT-EL/YQ-1822ZT-EL

- Heating Method:Heating by quartz heating tubes

-

Number of Electric Heating Tubes:2 pieces

- Roller Diameter:220mm

- Overview

- Recommended Products

Description

Electric Heat Transfer Machine

A compact, user-friendly device for efficient heat transfer applications on fabrics, plastics, ceramics, or metal surfaces. Equipped with electric heating elements, it delivers rapid, precise temperature control and even heat distribution for consistent transfer quality. Suitable for printing designs, logos, or textures onto apparel, promotional items, or industrial products. Features energy efficiency, low maintenance, and customizable settings (time/temperature) to adapt to various materials and production scales. Ideal for small to medium businesses or custom printing operations.

Specifications

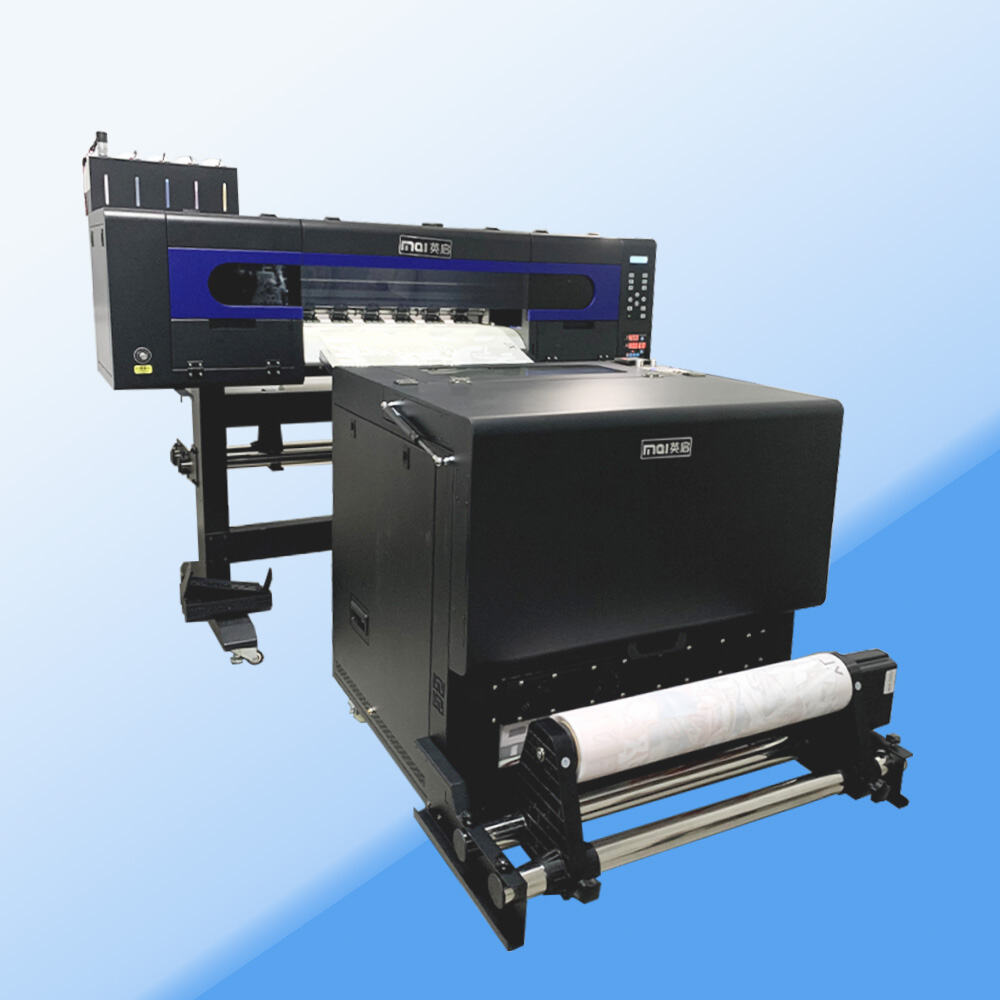

Specifications of 220-1200 Roller Thermal Transfer Machine (New):

Machine size: length 1380 * width 1780 * height 1360mm, heating method: quartz heating element heating, number of electric heating tubes: 2, roller diameter 220mm, roller surface: Teflon coating, voltage: 220/380V, heating power: 5.2KW, total power: 5.4kw, speed: 20-90 m/h, temperature range: 30-240 degrees, blanket width 1220mm, transfer width: 1120mm, unwinding system: 2 sets, winding system: 2 sets , Blanket adjustment form: manual adjustment, total machine size: length 1380 * width 1780 * height 1360mm, host size: length 1780 * width 500 * height 1360mm platform total size: length 930 * width 1430 * height 670mm, table size: length 600 * width 1370mm, wooden box packing size: length 1890 * 740 * 950mm, total weight of the machine: 260kg

Specifications of 220-1600 Roller Thermal Transfer Machine (New):

Machine size: length 1380 * width 2180 * height 1360mm, heating method: quartz heating element heating, number of electric heating pipes: 2, roller diameter 220mm, roller surface: Teflon coating, voltage: 220/380V, heating power: 6.4KW, total power: 6.6kw, speed: 20-90 m/h, temperature range: 30-240 degrees, blanket width 1620mm, transfer width: 1520mm, unwinding system: 2 sets, winding system: 2 sets , Blanket adjustment form: manual adjustment, total machine size: length 1380 * width 2180 * height 1360mm, host size: length 2180 * width 500 * height 1360mm platform total size: length 930 * width 1830 * height 670mm, table size: length 600 * width 1770mm, wooden box packing size: length 2290 * 740 * 950mm, total weight of the machine: 280kg

Specifications of 220-1800 Roller Thermal Transfer Machine (New):

Machine size: length 1380 * width 2380 * height 1360mm, heating method: quartz heating element heating, number of electric heating tubes: 2, roller diameter 220mm, roller surface: Teflon coating, voltage: 220/380V, heating power: 7.2KW, total power: 7.4kw, speed: 20-90 m/h, temperature range: 30-240 degrees, blanket width 1820mm, transfer width: 1720mm, unwinding system: 2 sets, winding system: 2 sets , Blanket adjustment form: manual adjustment, total machine size: length 1380 * width 2380 * height 1360mm, host size: length 2380 * width 500 * height 1360mm platform total size: length 930 * width 2030 * height 670mm, table size: length 600 * width 1970mm, wooden box packing size: length 2490 * 740 * 950mm, total weight of the machine: 320kg

Applications

Widely used in clothing, home textiles, leather products and other industries printing production.

Advantages

( 1 ) Excellent picture quality.

High resolution:

The printed images and text have clear and sharp edges, rich details, and can present both fine patterns and tiny text clearly, meeting the high quality requirements of users.

High color reproduction:

Accurately reproducing the colors of the original image, with high color saturation and appropriate contrast, the printed image is vivid and realistic in color, giving a strong visual impact.

Delicate color transition:

When printing gradient colors or images with rich color tone layers, it can avoid color discontinuity or stripe phenomenon, make color transition natural and smooth, and present a softer and more realistic picture effect.

( 2 ) High efficiency printing.

Significantly improving printing speed:

The dual print head configuration greatly enhances printing efficiency. On the premise of ensuring high-quality printing, the printing speed is significantly improved compared to single head printers. In daily production, more printing tasks can be completed per hour, greatly shortening the order delivery cycle and improving the production efficiency and market competitiveness of the enterprise.

Stable continuous printing performance:

The stable mechanical structure and optimized control system ensure the stable operation of the printer during long-term continuous printing processes. The key components such as the double print head and motor can work continuously and efficiently, avoiding overheating, lagging and other problems, ensuring the smooth progress of printing tasks, reducing downtime caused by equipment failures, and providing strong support for large-scale production.

( 3 ) Efficient printing.

Faster printing speed:

With the premise of ensuring high-quality printing, it has a relatively fast printing speed. Its printing speed can meet daily production needs and effectively improve work efficiency.

Good stability in continuous printing:

The stable mechanical structure and control system ensure the stability of the printer during long-term continuous printing processes. The key components such as the print head and motor can operate continuously and efficiently, avoiding problems such as overheating and lagging, ensuring the smooth progress of printing tasks, reducing downtime caused by equipment failures, and improving production efficiency.

FAQ

Q:What should I do if the print head of the printer is blocked?

A:The printer is equipped with an automatic cleaning and ink scraping system. When there is a slight blockage in the print head, the automatic cleaning function can be activated through the printer's control panel. This function uses cleaning solution to clean the print head and usually solves the blockage problem. If the blockage still cannot be resolved after automatic cleaning, it may be due to severe blockage of the print head. In this case, we need to contact our after-sales technical personnel for handling. After sales technicians will use more professional cleaning methods, such as soaking and cleaning with specialized print head cleaning solution. It is not recommended for users to disassemble the print head for cleaning on their own to avoid damaging the print head.

Q:Can it be printed on media of different thicknesses?

A:This printer can print on media within a certain thickness range. When printing media of different thicknesses, it is necessary to adjust the relevant parameters of the printer appropriately according to the thickness of the media, such as the height of the print head, pressure, etc., to ensure that the appropriate distance is maintained between the print head and the media, and to ensure the printing effect. The specific adjustment method can refer to the printer's operation manual or consult the after-sales technical personnel.

Q:How long is the warranty period for the printer?

A:In general, the entire printer comes with a one-year warranty service, and core components such as print heads, motors, control systems, etc. are also covered by a one-year warranty. During the warranty period, if the equipment malfunctions due to non-human factors, the manufacturer will provide free repair services. However, it should be noted that users should operate and maintain the equipment correctly according to the printer's user manual, otherwise it may affect warranty rights. If the device exceeds the warranty period, users can still contact after-sales technicians for repairs, but they will need to pay the corresponding repair fees.